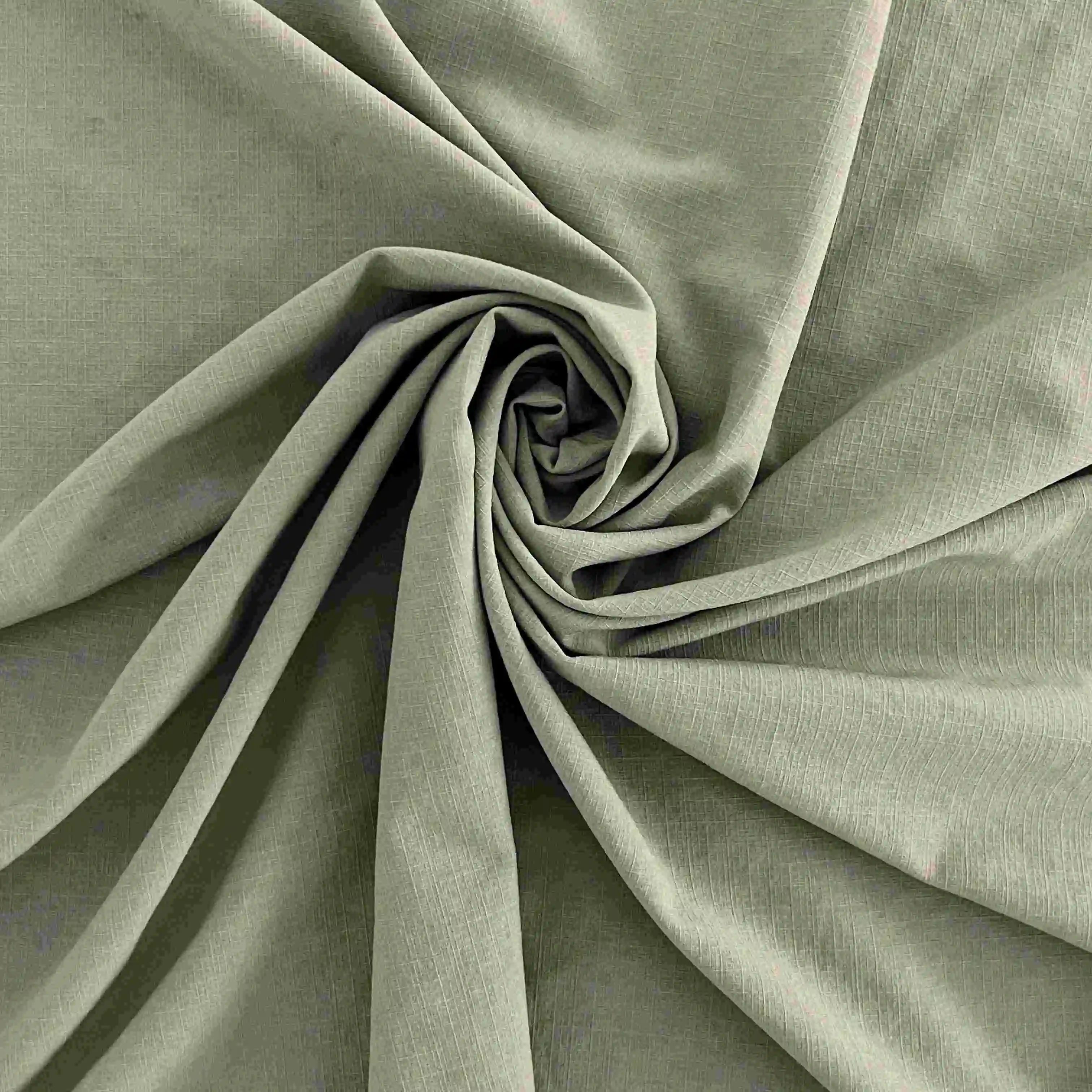

apparel fabric manufacturer

An apparel fabric manufacturer stands as a vital cornerstone in the global textile industry, specializing in the production of high-quality materials for clothing and fashion applications. These manufacturers employ state-of-the-art machinery and advanced production techniques to create diverse fabric selections, from natural fibers to synthetic blends. Their facilities typically encompass comprehensive production lines that handle everything from fiber processing to fabric finishing, ensuring consistent quality throughout the manufacturing process. Modern apparel fabric manufacturers integrate cutting-edge technology like automated quality control systems, sustainable production methods, and innovative dyeing techniques. They maintain strict quality standards while adhering to international safety regulations and environmental guidelines. These facilities often feature specialized departments for research and development, focusing on creating new fabric compositions and improving existing ones to meet evolving market demands. The manufacturers work closely with fashion brands, designers, and retailers, providing customized solutions for specific clothing applications. Their expertise extends to developing fabrics with enhanced properties such as moisture-wicking, UV protection, and temperature regulation, catering to both functional and aesthetic requirements of contemporary apparel.