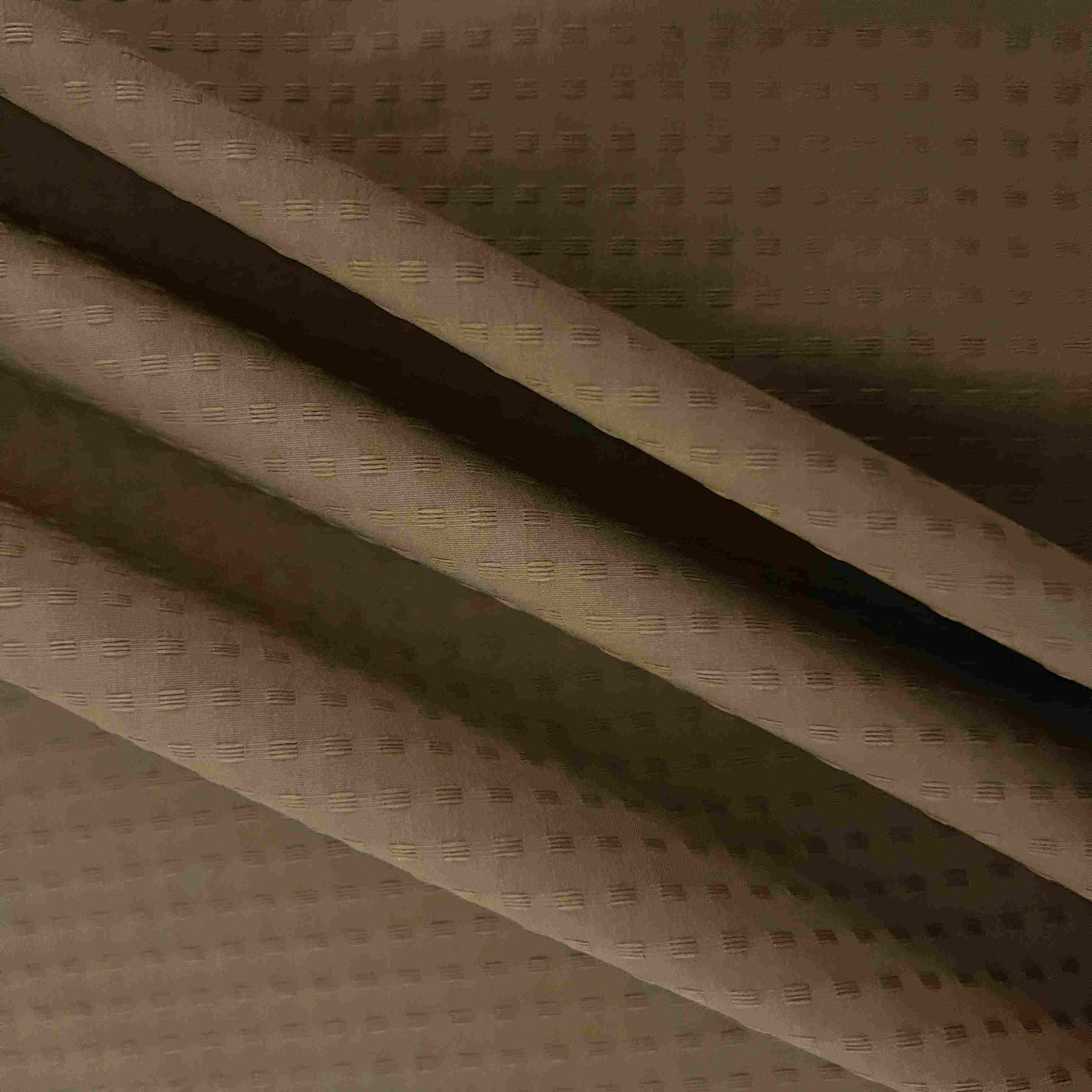

blended material

The blended material represents a cutting-edge composite solution that combines advanced polymer technology with sustainable raw materials to create a versatile and high-performance product. This innovative material showcases exceptional durability and adaptability across various applications, featuring a unique molecular structure that enables superior strength-to-weight ratios while maintaining flexibility. The material's composition includes carefully selected compounds that work synergistically to enhance thermal stability, chemical resistance, and mechanical properties. Through sophisticated processing techniques, the material achieves uniform distribution of components, resulting in consistent performance characteristics throughout its structure. Its advanced formulation allows for customizable properties, making it suitable for diverse industrial applications, from automotive components to consumer goods. The material exhibits remarkable resistance to environmental factors, including UV radiation and moisture, while maintaining its structural integrity over extended periods. Furthermore, the manufacturing process incorporates eco-friendly practices, reducing environmental impact while meeting stringent quality standards. The material's versatility extends to various forming methods, including injection molding, extrusion, and compression molding, providing manufacturers with flexibility in production processes.