sustainable activewear fabrics

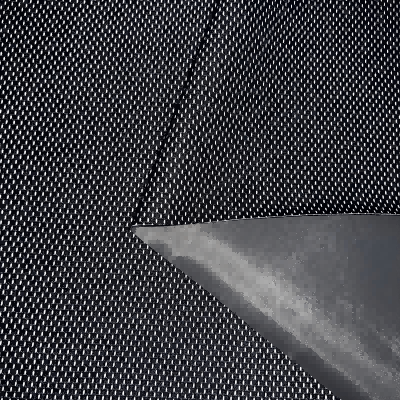

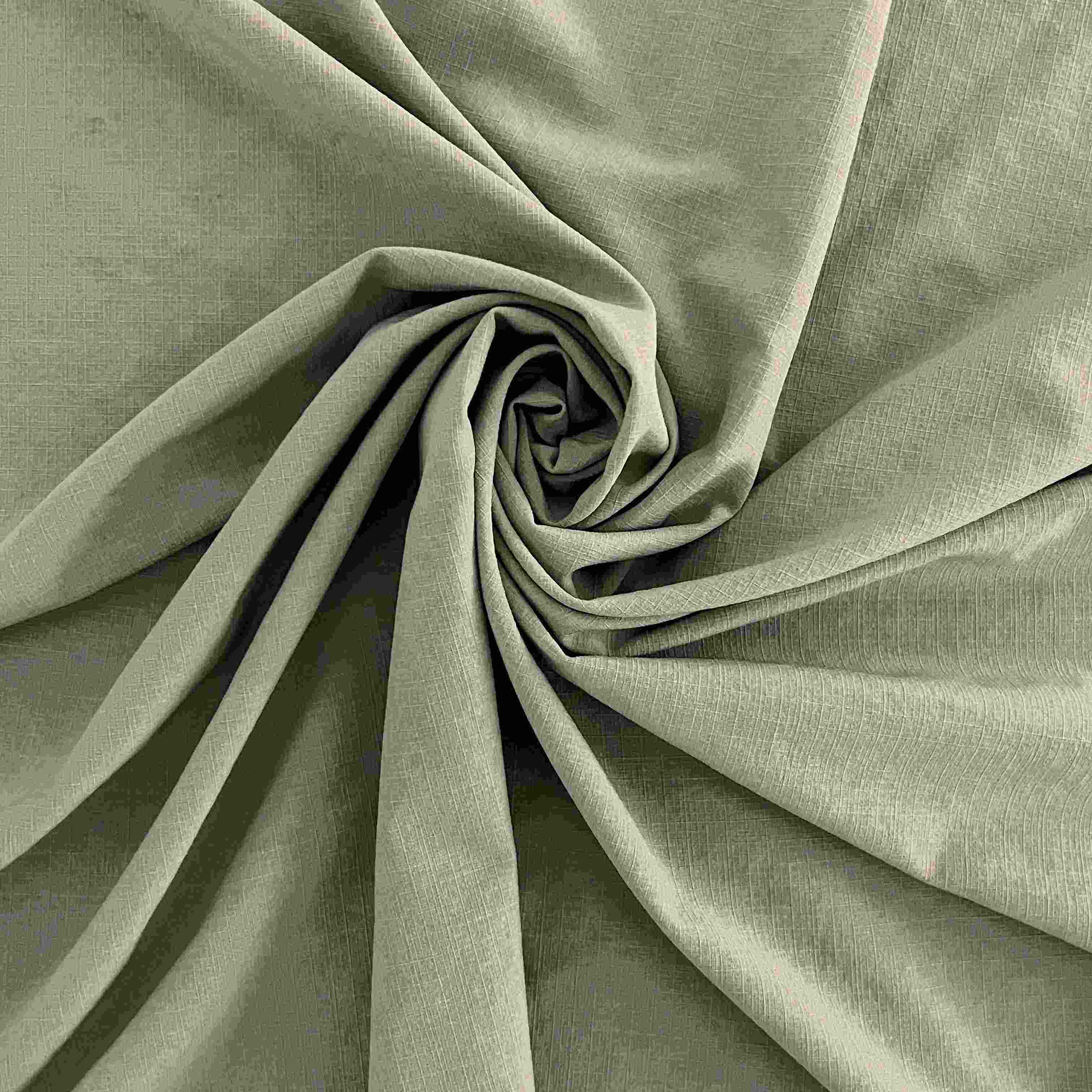

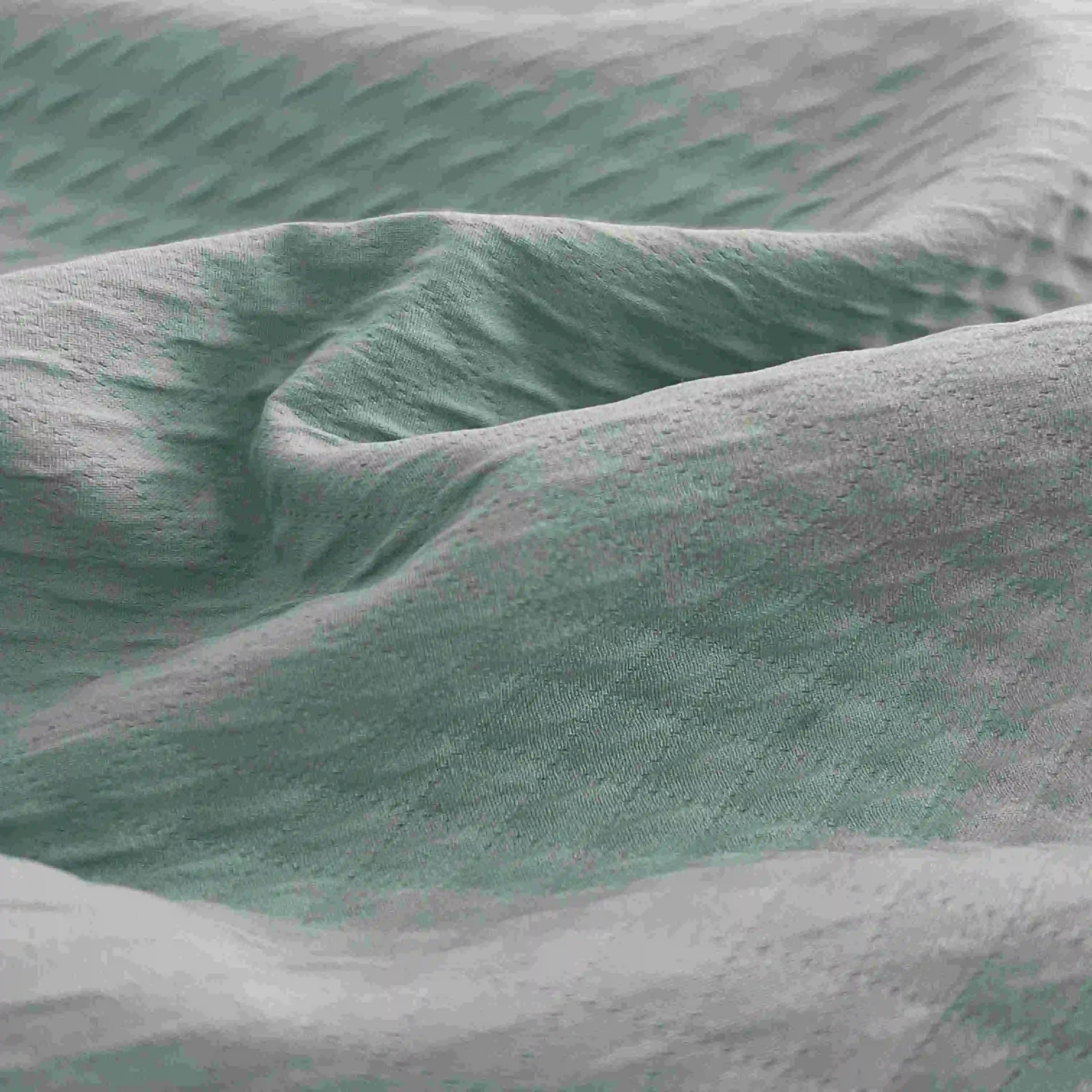

Sustainable activewear fabrics represent a revolutionary advancement in athletic apparel, combining environmental consciousness with high performance functionality. These innovative materials are engineered from eco-friendly sources such as recycled polyester, organic cotton, and regenerated nylon, offering superior moisture management and durability while minimizing environmental impact. The fabrics incorporate cutting-edge technologies like moisture-wicking properties, four-way stretch capabilities, and antimicrobial treatments, ensuring optimal comfort during intense physical activities. These materials undergo rigorous testing to maintain quality standards while reducing water consumption and carbon emissions during production. Many sustainable activewear fabrics feature advanced temperature regulation systems, allowing athletes to maintain optimal body temperature regardless of external conditions. The materials are designed to withstand repeated washing and wear while maintaining their shape and performance characteristics. Contemporary sustainable activewear fabrics also integrate UV protection and quick-drying properties, making them ideal for both indoor and outdoor activities. The manufacturing process emphasizes circular economy principles, utilizing recycled materials and ensuring the end product remains recyclable, creating a closed-loop system that significantly reduces waste in the textile industry.