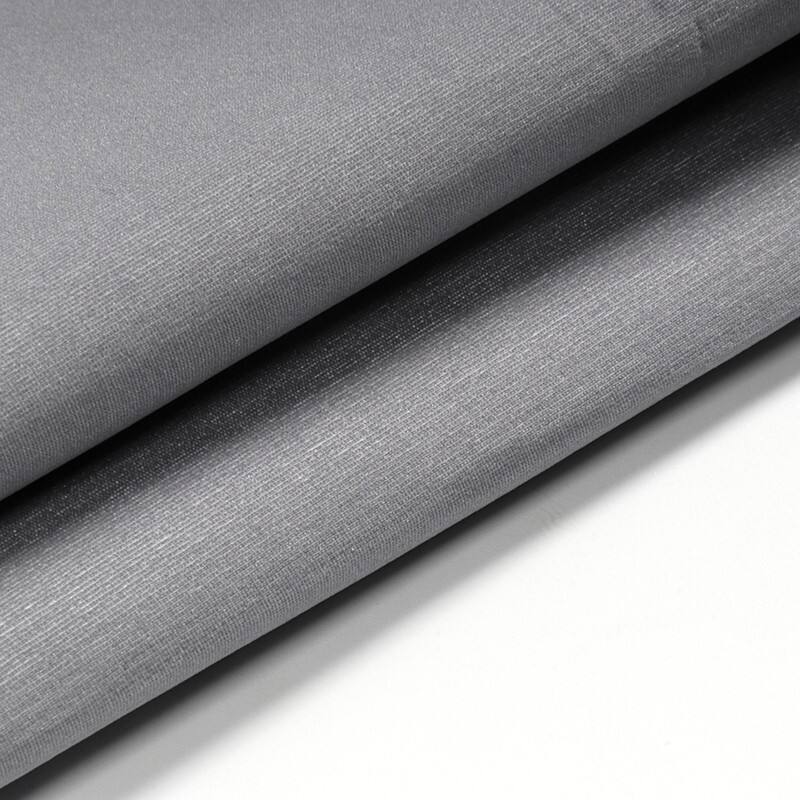

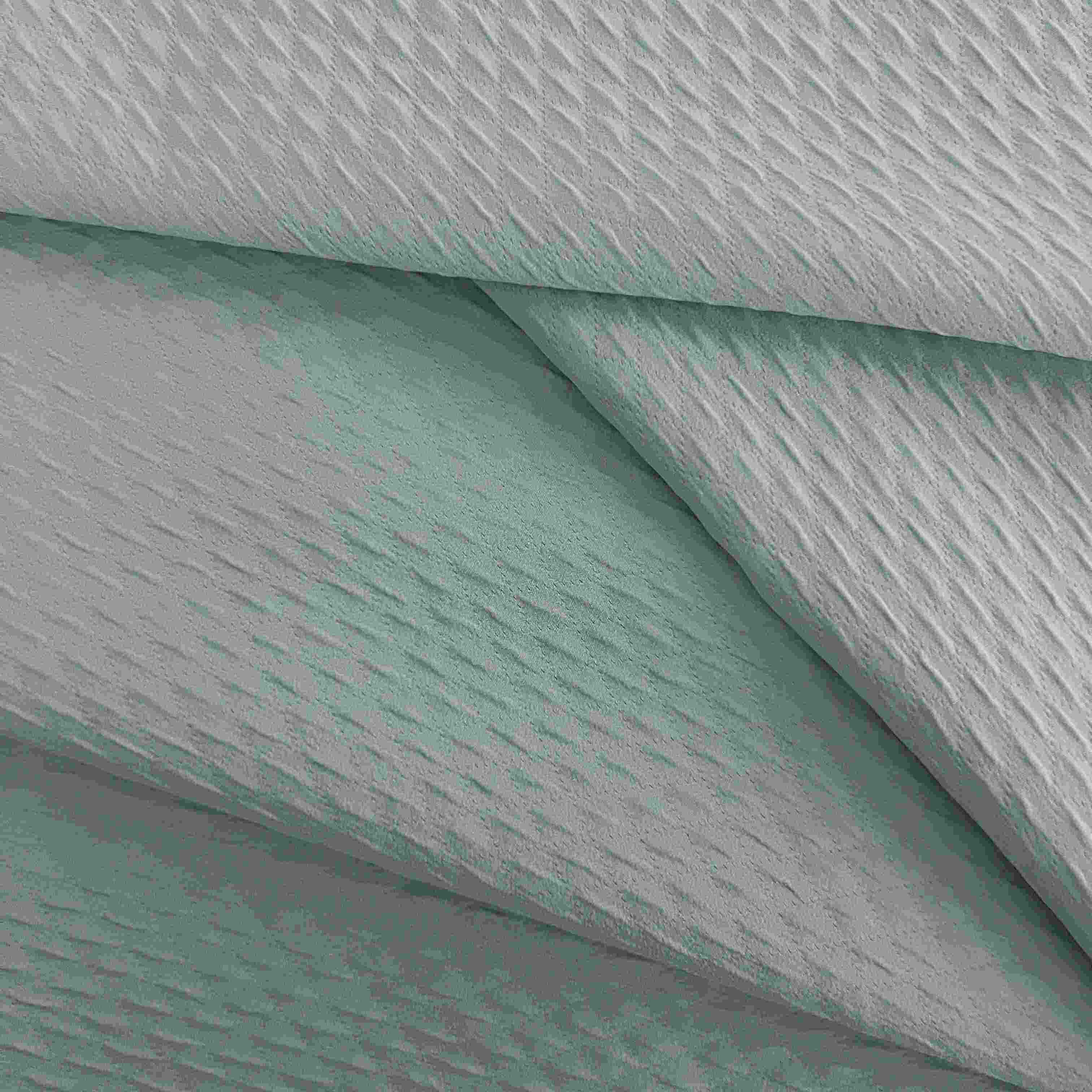

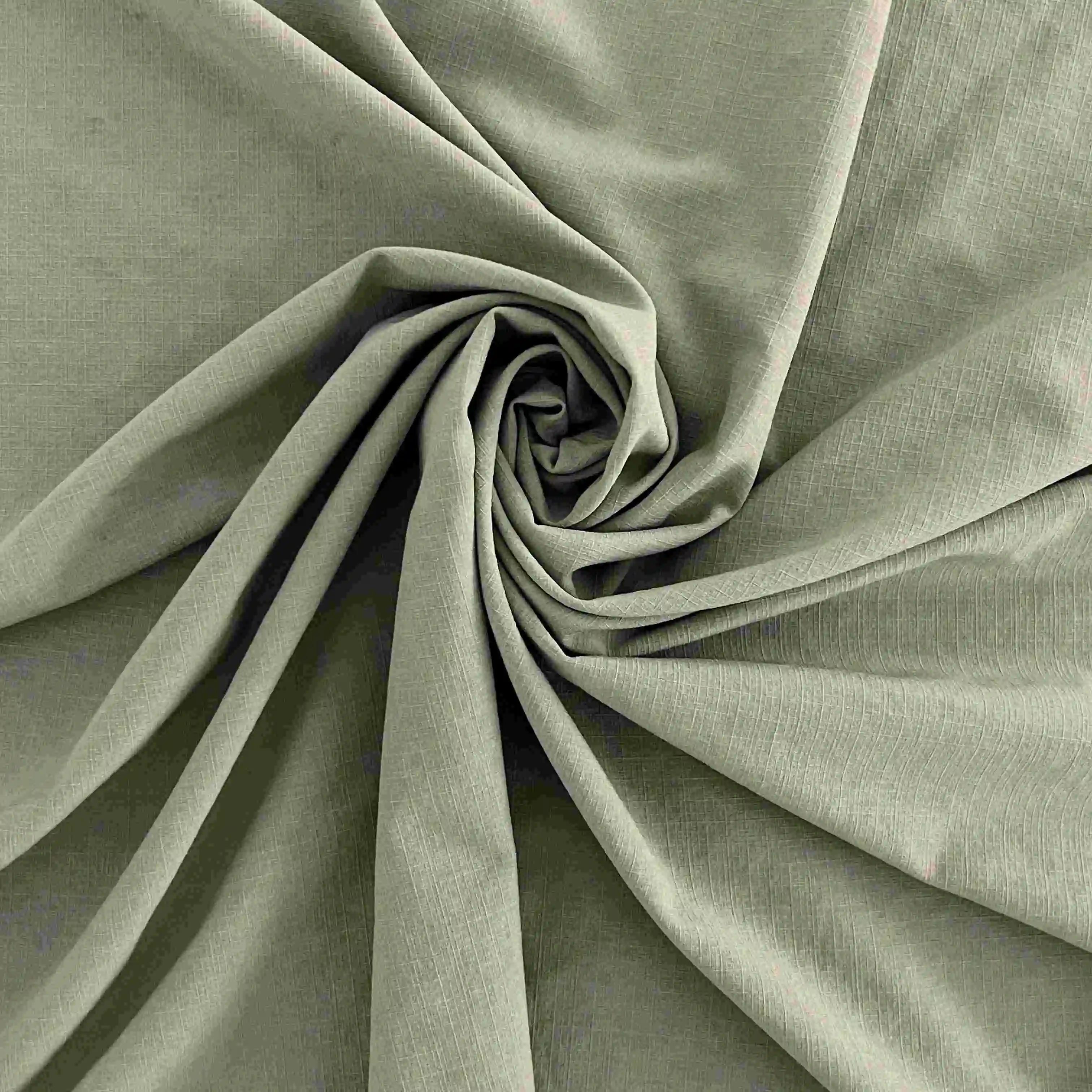

technical textile fabrics

Technical textile fabrics represent a sophisticated evolution in textile engineering, combining advanced materials and innovative manufacturing processes to create high-performance materials. These specialized fabrics are engineered to deliver specific functional properties beyond traditional textiles, including enhanced durability, moisture management, temperature regulation, and protective capabilities. The fabrics incorporate various synthetic and natural fibers, often treated with cutting-edge finishes and coatings to achieve desired performance characteristics. They feature precise fiber arrangements, specialized weaving patterns, and controlled porosity levels to meet specific technical requirements. Applications span across multiple industries, from medical and protective gear to automotive and aerospace components. The fabrics can be customized for UV protection, flame resistance, antimicrobial properties, and electrical conductivity. Modern technical textiles also emphasize sustainability, incorporating recycled materials and eco-friendly production methods while maintaining high-performance standards. These materials undergo rigorous testing and quality control processes to ensure consistent performance and reliability across various environmental conditions and use cases.