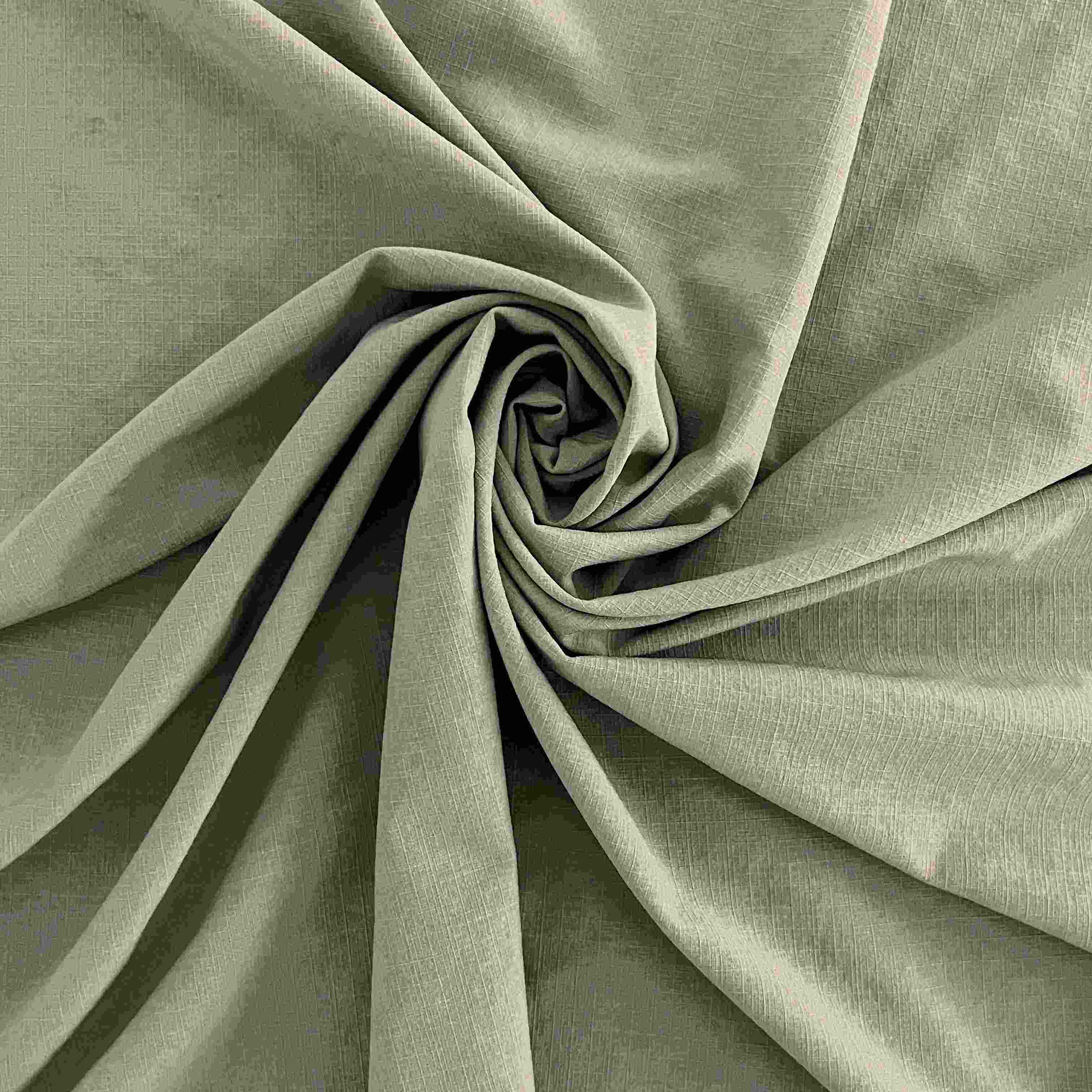

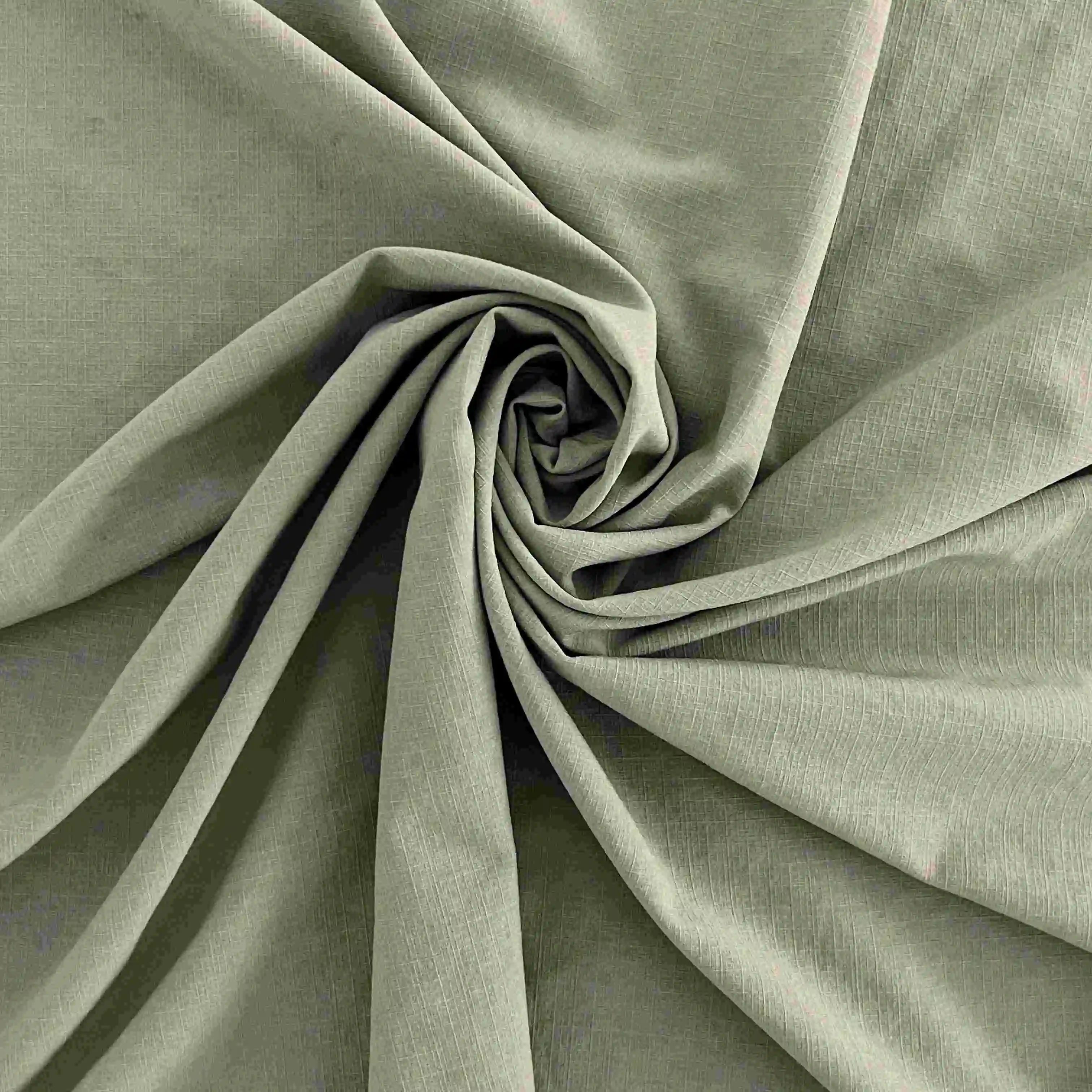

waterproof fabric manufacturer

A waterproof fabric manufacturer stands at the forefront of innovative textile production, specializing in creating high-performance materials that effectively resist water penetration while maintaining breathability. These manufacturers employ cutting-edge technology and advanced manufacturing processes to develop fabrics that serve various industries, from outdoor gear to protective workwear. The production facilities utilize state-of-the-art equipment to apply specialized treatments and coatings, ensuring consistent quality and durability in their waterproof materials. The manufacturing process involves multiple quality control stages, from raw material selection to final testing, guaranteeing that each batch meets strict waterproofing standards. These facilities often incorporate sustainable practices, using eco-friendly materials and reducing water consumption during production. The manufacturers maintain research and development departments dedicated to improving existing formulations and developing new waterproofing technologies. They offer customization options to meet specific client requirements, including varying degrees of water resistance, breathability levels, and fabric weights. Their expertise extends to creating both membrane-based and coating-based waterproof solutions, catering to different application needs and performance requirements.