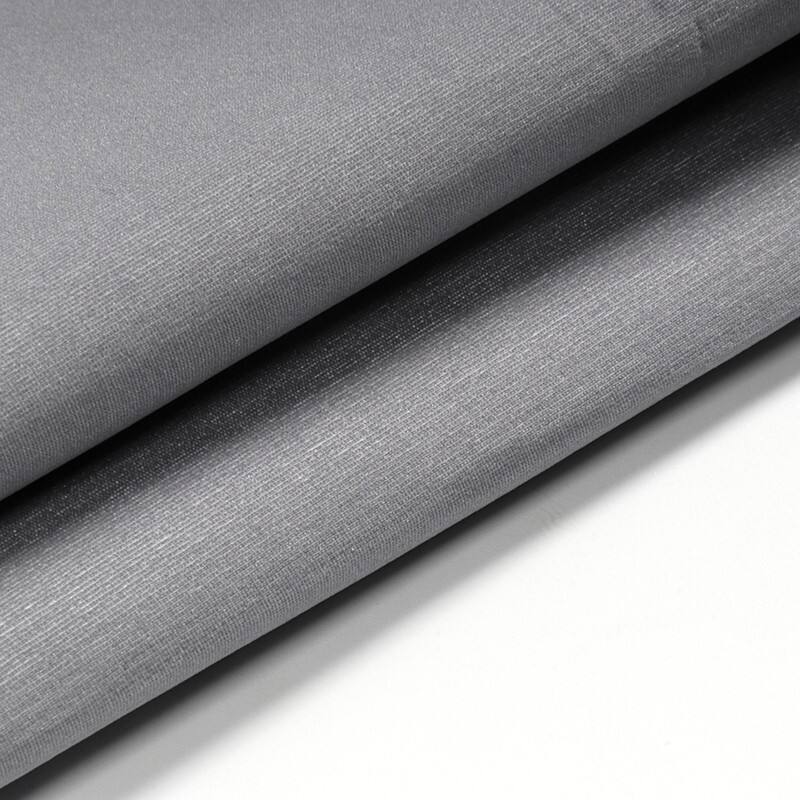

woven technical textiles

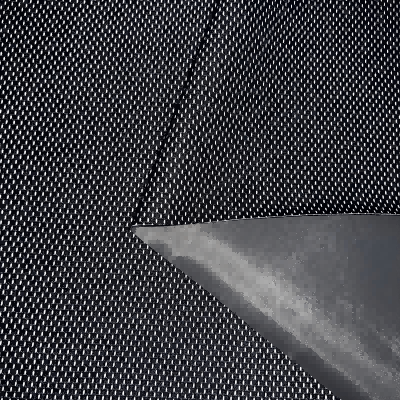

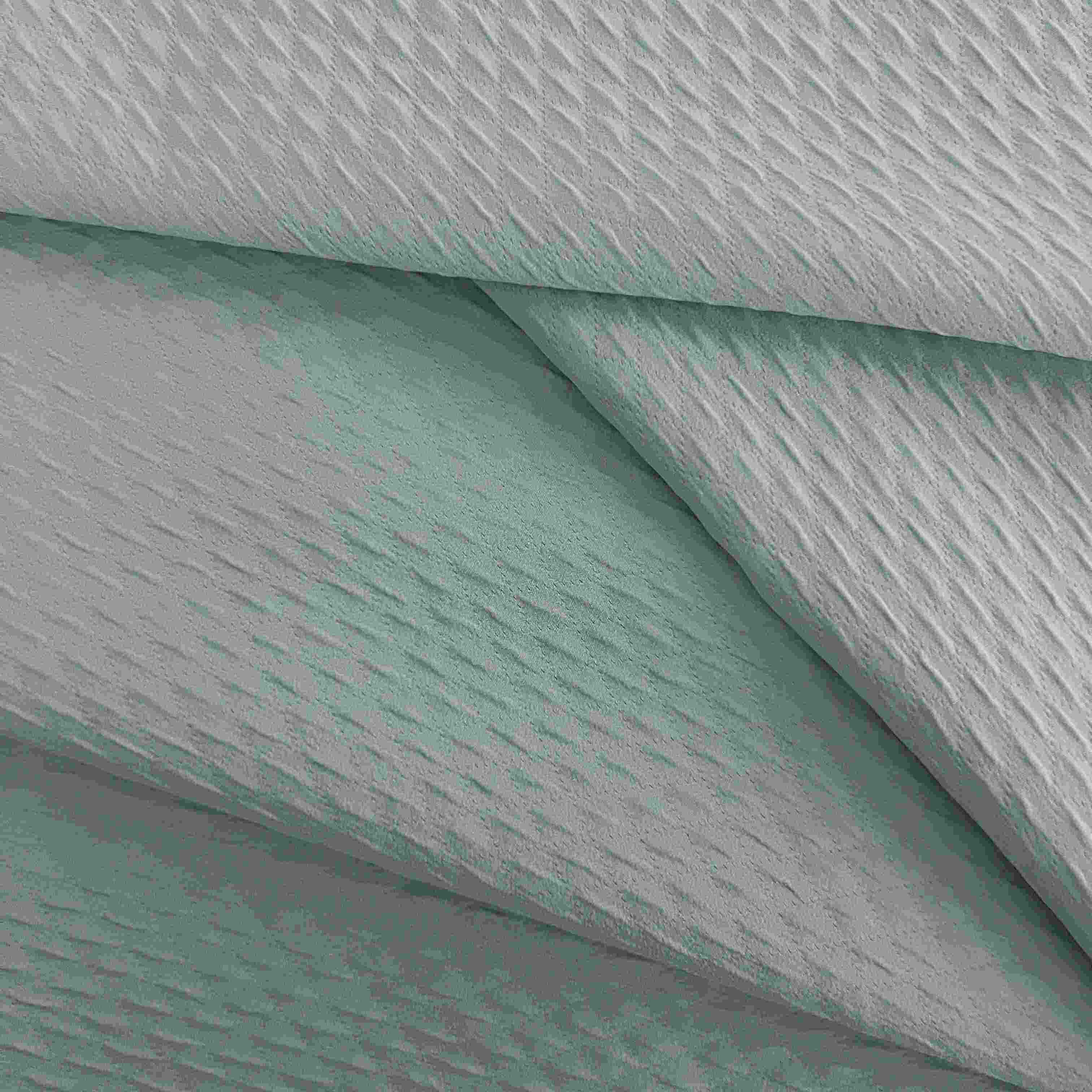

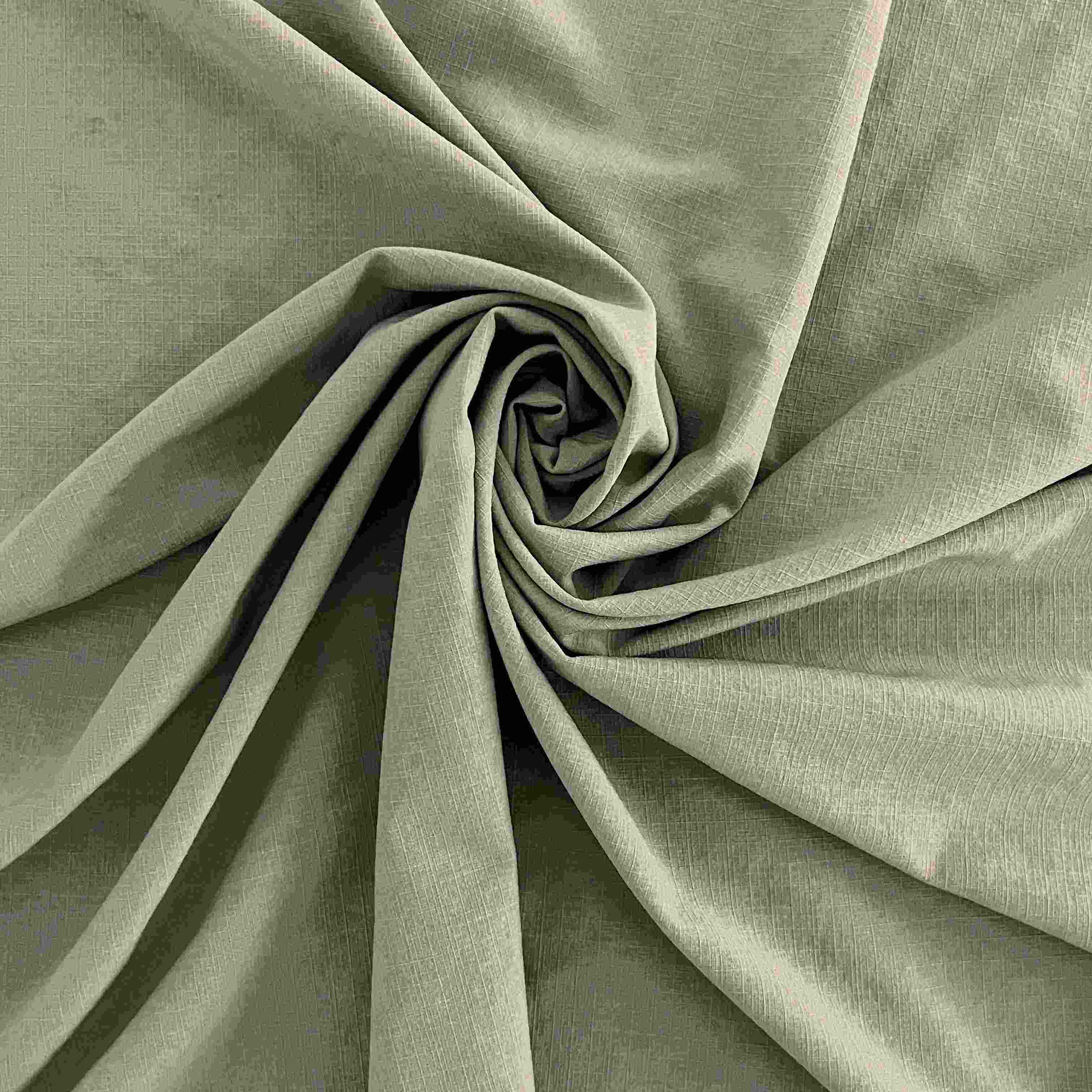

Woven technical textiles represent a sophisticated category of engineered fabrics designed for specific performance requirements rather than aesthetic appeal. These specialized materials are manufactured through advanced weaving processes that interlace two sets of yarns at right angles, creating stable and durable structures. The manufacturing process involves state-of-the-art weaving machinery that can produce complex patterns and structures, enabling the creation of fabrics with precise specifications for strength, durability, and functionality. These textiles find applications across diverse industries, from aerospace and automotive to medical and protective clothing. Their unique properties include exceptional tensile strength, dimensional stability, and resistance to various environmental factors. The materials can be engineered to provide specific characteristics such as fire resistance, chemical protection, or electromagnetic shielding. In industrial applications, these textiles serve as reinforcement materials in composites, filtration media, and geotextiles. The medical sector utilizes them in surgical implants, wound dressings, and sterile barriers. The construction industry employs them for structural reinforcement, while the transportation sector relies on them for airbags and seat belts. The versatility of woven technical textiles makes them indispensable in modern technological applications, where traditional materials may not meet the demanding performance requirements.