textile reticulatum amicum naturae

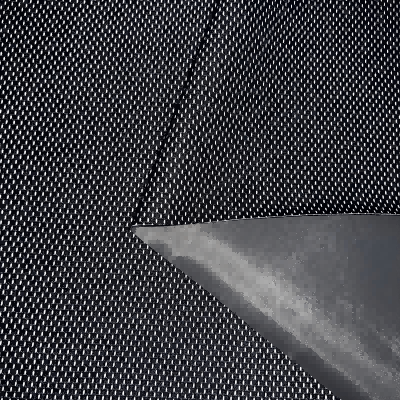

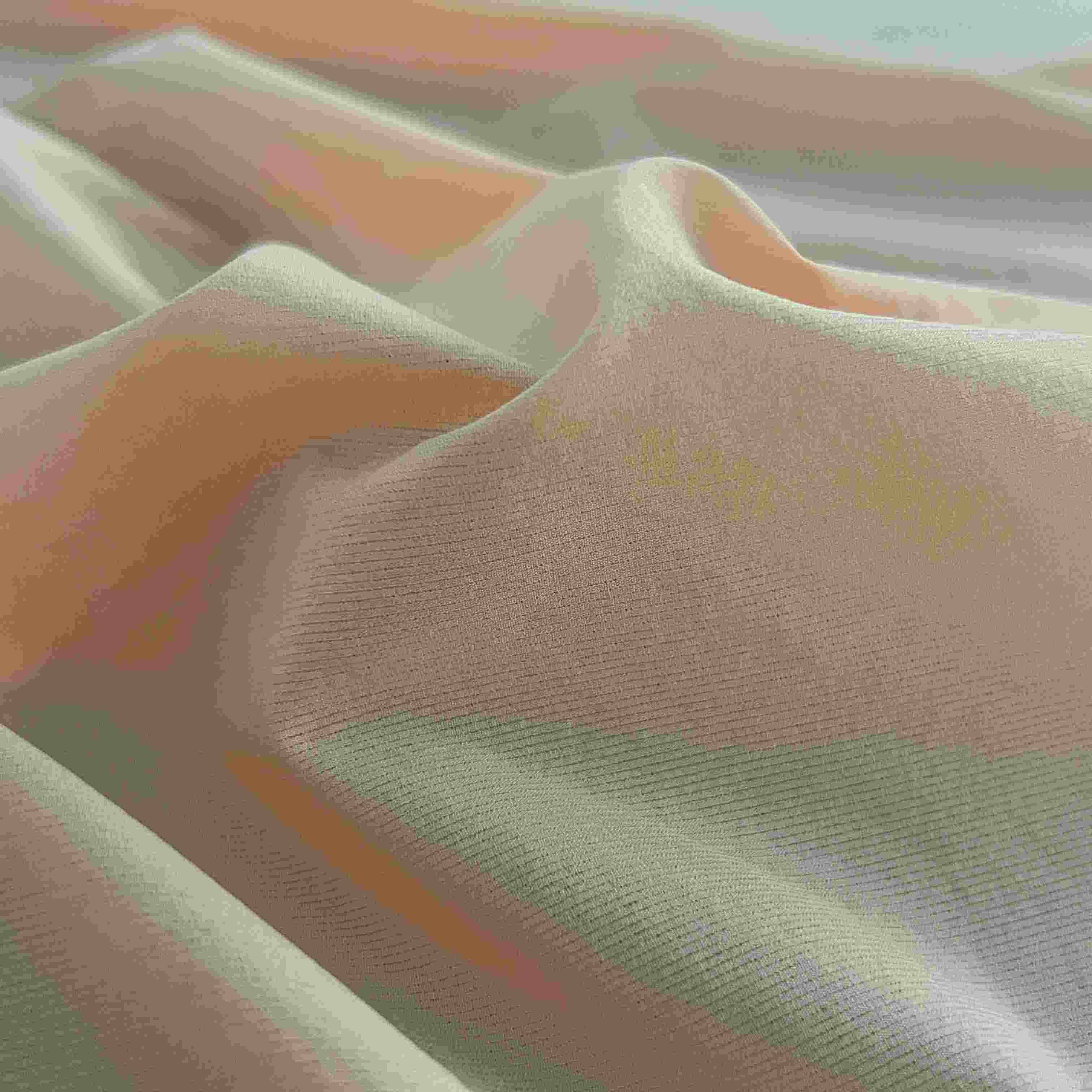

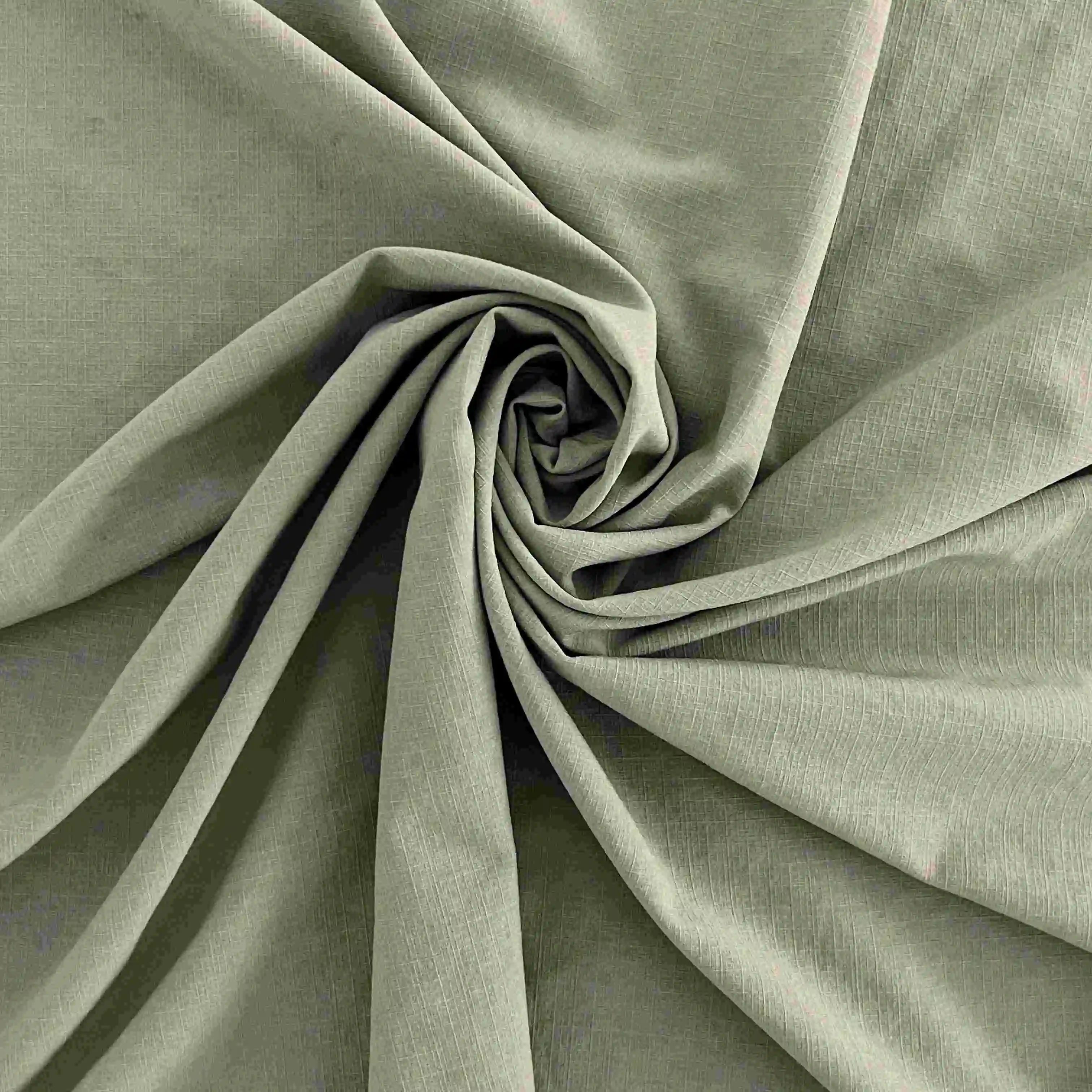

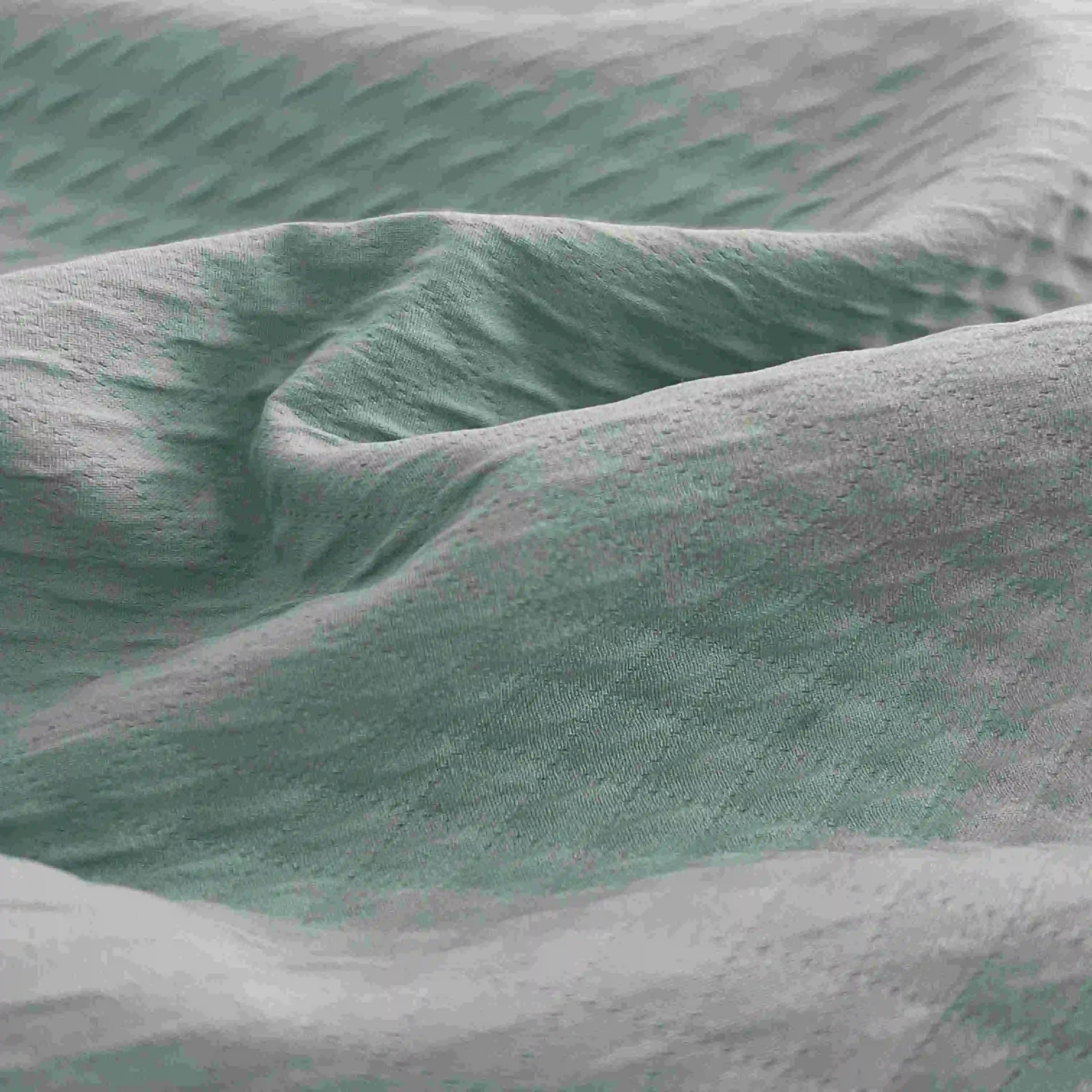

Tela reticular amica naturae repraesentat progressum notabilem in fabricando textili sustinabili, combinet conscientiam environmentalis cum functione practica. Hoc materia novator est confectum ex fibrillis polyester recycletis aut alternativis biodegradabilibus, offert solutionem responsabilem ad sollicitudinem crescentem de residuis textilibus et impactu environmentali. Tela praebet structuram distinctam reticulam que promovet respirabilitatem exceptionalem dum robur et fortitudinem conservat. Constructio unica eius permittit circulationem aeris optima et administrationem umoris, faciens id aptum pro variis applicationibus ab vestimentis athleticis usque ad mobilia exteriora. Processus fabricandi tela reticularis amicae naturae utitur usque ad 50% minus energie comparatum ad methodos traditionales fabricandi textilis et reducit consumptio aquae per circiter 60%. Materia subit experimenta qualitatis rigida ad certificandum quod standardes performance servet dum proprietates eco-conscientes conservat. Technica tingendi advanced usae in productione sunt aquae basatae et liberae ab chemicalibus noxious, ulterius reducendo impactum environmentalis. Versoritas telae monstratur per suam capacitatem ad customizationem in pondere, capacitate extensiva, et densitate schematis, faciens eam aptam pro applicationibus diversis inter multas industrias.