non texturae biodegradable

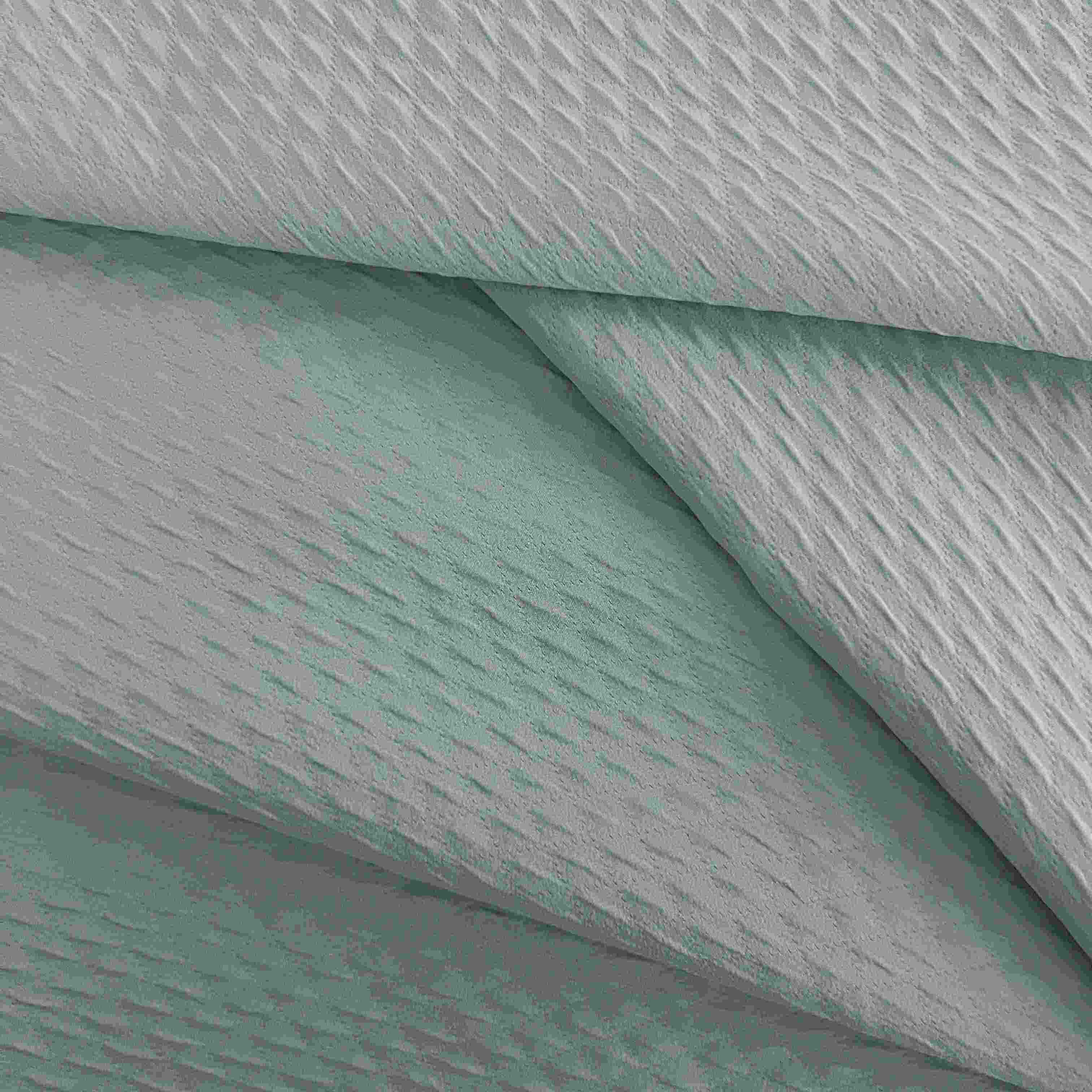

Tela non woven biodegradabilis significat progressum revolutionarium in fabrica textilium sustentabilium. Hoc materia novum coniungit versatilem naturam telarum non woven traditionalium cum proprietatibus decompositionis amicabilium ecologiam. Tela creatur per processum specialis ubi fibræ naturales, sicut materiales plantares inter quos amylum frumenti, bambus, aut PLA (Polylactic Acid), conglutinantur absque texendo. Materia resultans monstrat vim et durabilitatem mirabiles dum retinet suas proprietates biodegradabiles. Quando in conditionibus aptis projicitur, hæc tela naturaliter discidit in composita innoxia, typice intra 3 ad 6 menses, relinquens nullas reliquias noxias in environmente. Technologia post tergum telarum non woven biodegradabilium involvit selectionem curatam materialium primigenorum et processus conglutinationis innovatores qui servant integritatem structuralem durante usu sed permitunt decompositionem naturalem postea. Hæc materia invenit applicationes extensas in variis sectoribus, inclusis supellectilibus medicalibus, tegimentis agriculturalibus, productis hygienicis desinentibus, et package amicabili ecologiam. Potestas telæ de servando characteristicas performance dum offert beneficia environmentalia fecit eam crescenter popularis in industriis quaerentibus alternativas sustentabiles ad materiales syntheticos traditionales.