custom nylon fabric

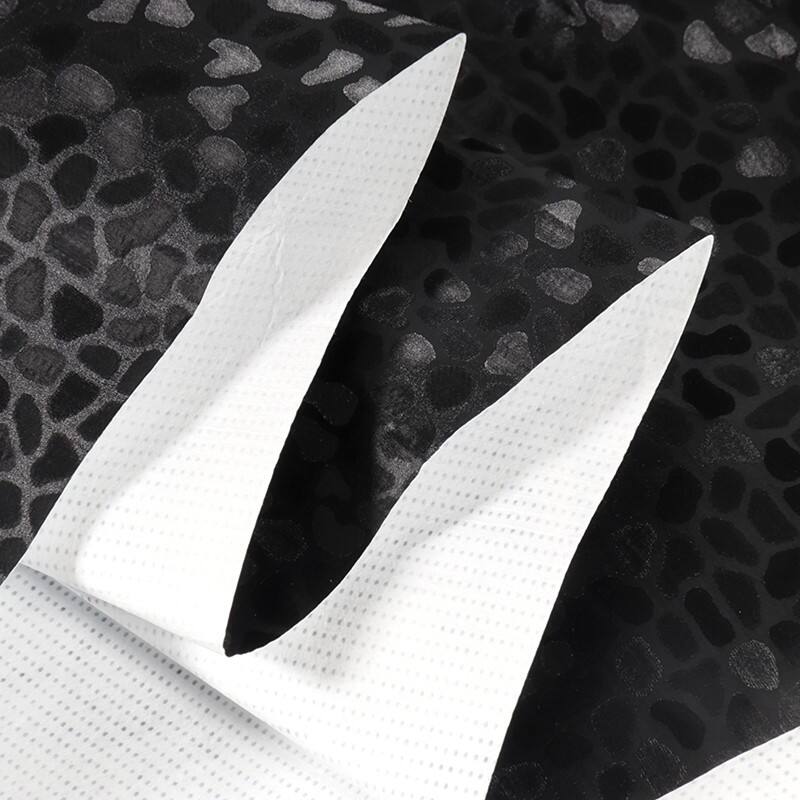

Custom nylon fabric represents a versatile and innovative textile solution that combines durability with adaptability. This engineered material features a synthetic polymer structure that can be customized to meet specific performance requirements. The fabric undergoes specialized manufacturing processes that allow for adjustments in density, thickness, and surface treatment, resulting in a material that can be tailored for diverse applications. Custom nylon fabric exhibits exceptional strength-to-weight ratio, remarkable resistance to wear and tear, and outstanding moisture-wicking properties. Its molecular structure can be modified to enhance specific characteristics such as UV resistance, water repellency, or thermal insulation. The fabric finds extensive use in outdoor gear, athletic wear, industrial applications, and protective equipment. Manufacturers can adjust the denier count, weave pattern, and finishing treatments to achieve desired performance characteristics. The material's inherent flexibility allows for various dyeing and printing processes, enabling unique aesthetic possibilities while maintaining functional properties. Custom nylon fabric also demonstrates excellent recovery properties, maintaining its shape and performance characteristics even after repeated use and washing cycles.