nylon fabric manufacturer

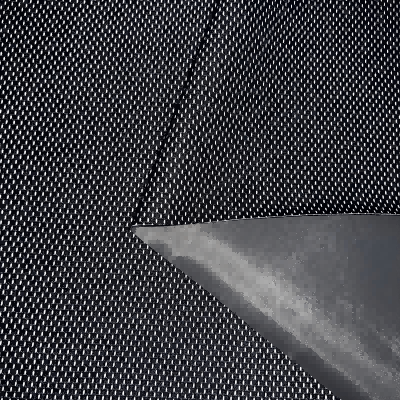

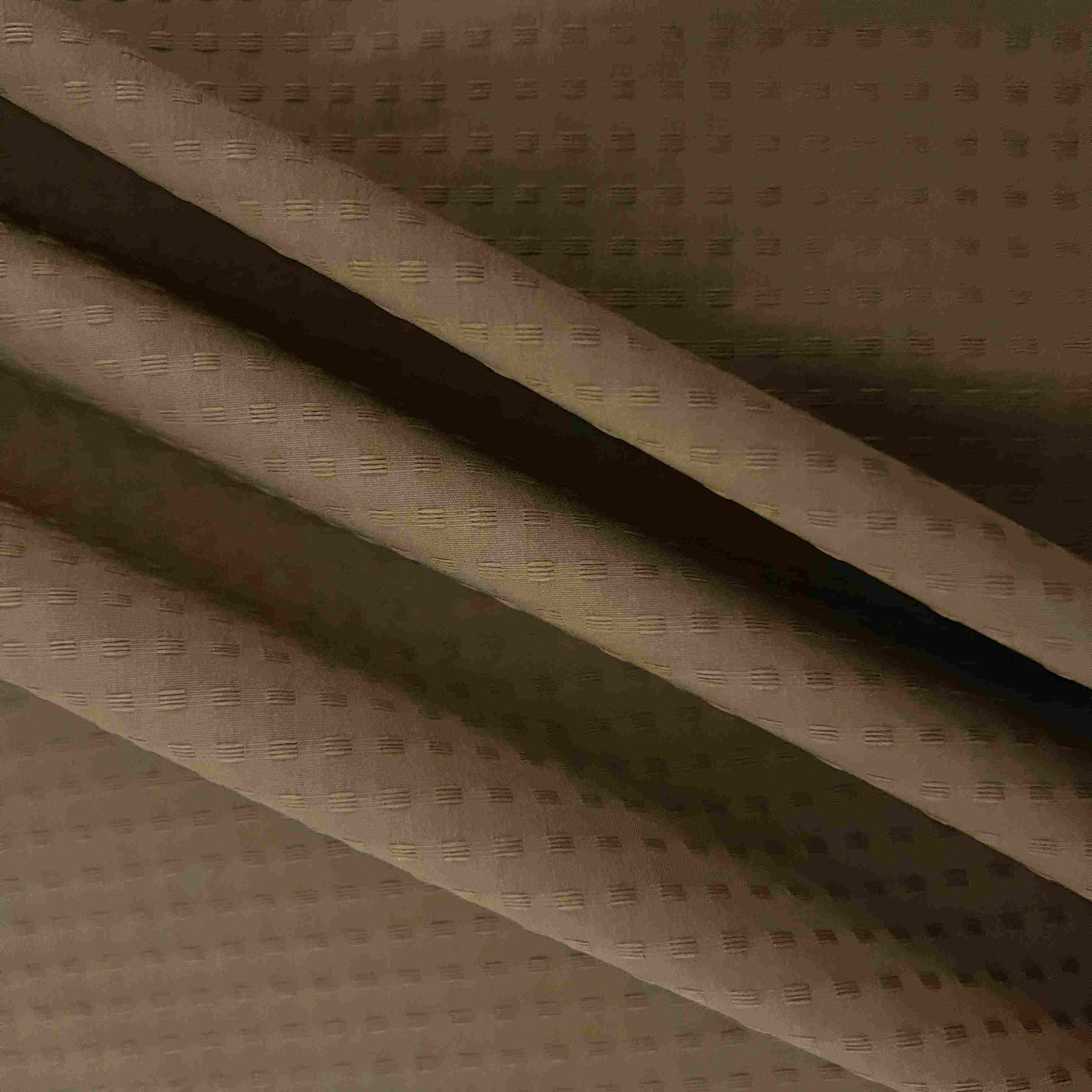

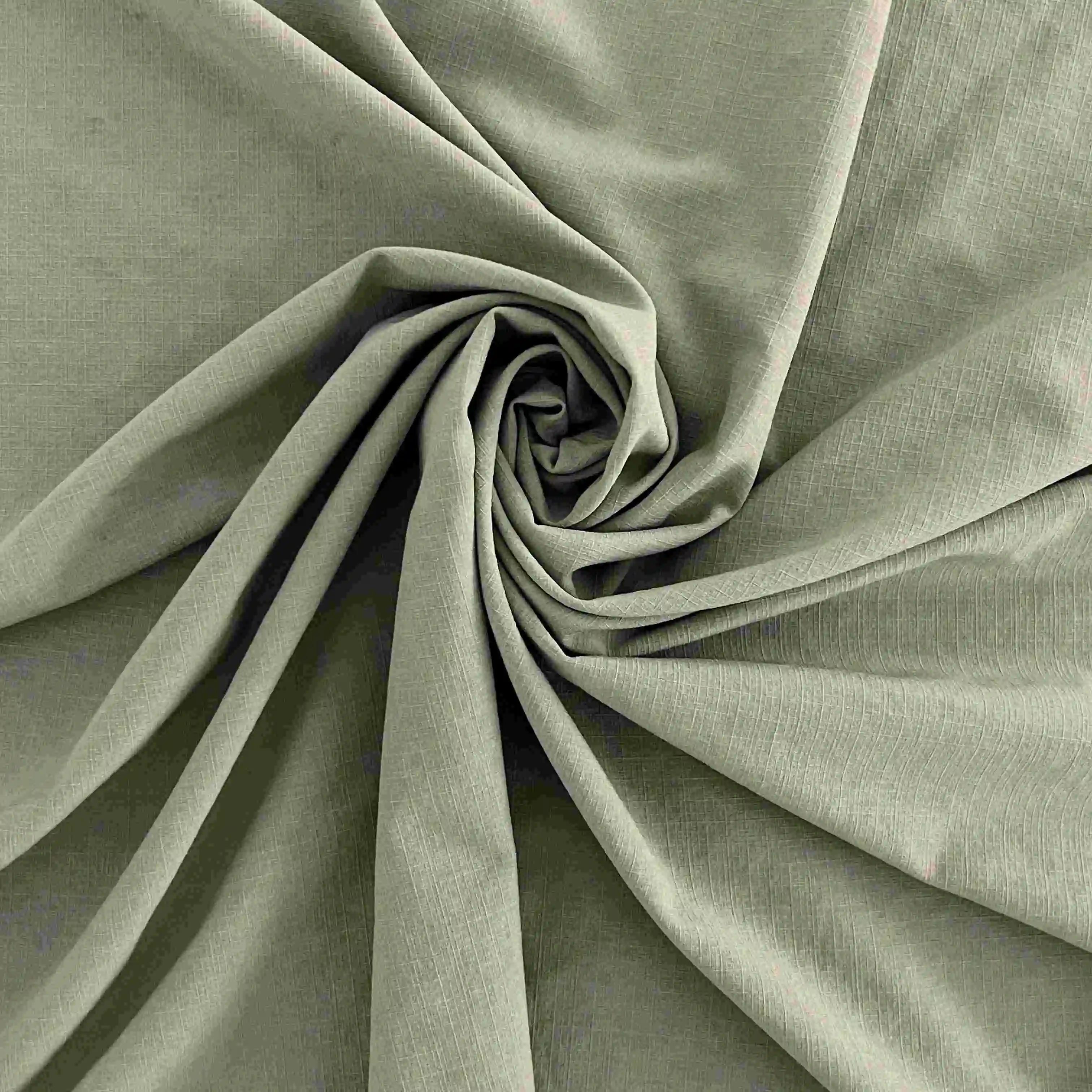

A nylon fabric manufacturer stands as a cornerstone in the textile industry, specializing in the production of versatile synthetic materials that have revolutionized modern manufacturing. These facilities employ cutting-edge technology and advanced production methods to create high-quality nylon fabrics that meet diverse industrial and consumer needs. The manufacturing process involves the careful manipulation of polymer chains through extrusion, drawing, and texturing to produce fibers with specific characteristics. These facilities utilize state-of-the-art equipment for weaving, knitting, and finishing processes, ensuring consistent quality and performance across all products. The manufacturer's capabilities typically extend to producing various nylon fabric types, including ripstop, taffeta, mesh, and microfiber constructions, each engineered for specific applications. Quality control measures are implemented at every production stage, from raw material selection to final product testing, ensuring durability, strength, and reliability. Modern nylon fabric manufacturers also emphasize sustainability, incorporating eco-friendly practices and recycled materials into their production processes while maintaining high performance standards.