Revolutionizing the Textile Industry Through Innovative Materials

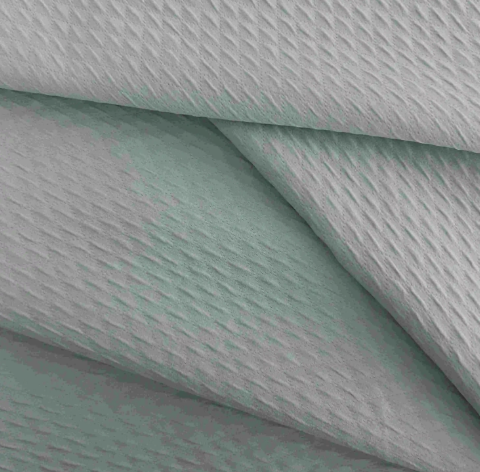

The textile landscape is experiencing a remarkable transformation with non-woven fabrics leading the charge into a new era of manufacturing and sustainability. These versatile materials, created by bonding or interlocking fibers through mechanical, thermal, or chemical processes, have emerged as game-changers in multiple industries. From medical supplies to fashion, agriculture to automotive applications, non-woven fabrics are reshaping our understanding of textile possibilities and challenging traditional manufacturing methods.

As global demands for sustainable, cost-effective, and versatile materials continue to rise, non-woven fabrics stand at the forefront of innovation. Their unique production process eliminates the need for spinning yarn or weaving, resulting in faster manufacturing times and reduced resource consumption. This revolutionary approach to textile production has captured the attention of industry leaders and environmental advocates alike.

Understanding Non-Woven Fabric Technology

Production Methods and Techniques

The manufacturing of non-woven fabrics involves sophisticated processes that differ significantly from traditional textile production. The primary methods include spunbonding, meltblowing, and needlepunching. Each technique creates materials with distinct characteristics and applications. Spunbonding, for instance, produces strong, durable fabrics ideal for construction and automotive uses, while meltblowing creates ultra-fine fibers perfect for filtration and medical applications.

Advanced technology plays a crucial role in non-woven fabric production, enabling manufacturers to precisely control fiber distribution, thickness, and material properties. This level of control results in consistent quality and customizable characteristics that meet specific industry requirements.

Material Science and Innovation

The science behind non-woven fabrics continues to evolve, with researchers developing new fiber combinations and bonding methods. These innovations have led to materials with enhanced properties, such as improved strength-to-weight ratios, better moisture management, and increased durability. The ability to incorporate various raw materials, from natural fibers to synthetic polymers, provides unprecedented flexibility in material design.

Recent developments in nanotechnology have further expanded the possibilities for non-woven fabrics. Nanofibers and smart materials are being integrated into non-woven structures, creating fabrics with advanced functionalities like self-cleaning properties, thermal regulation, and electromagnetic shielding.

Environmental Impact and Sustainability

Resource Efficiency in Production

Non-woven fabrics represent a more environmentally conscious approach to textile manufacturing. The streamlined production process requires less water, energy, and chemical treatments compared to traditional woven or knitted fabrics. This efficiency translates to a smaller environmental footprint and reduced production costs, making non-woven fabrics an attractive option for eco-conscious manufacturers and consumers.

The industry's commitment to sustainability extends to raw material selection, with many manufacturers incorporating recycled fibers and biodegradable components into their non-woven products. This approach helps address the growing concern over textile waste and supports circular economy initiatives.

End-of-Life Considerations

The environmental impact of non-woven fabrics extends beyond production to their end-of-life phase. Many modern non-woven materials are designed for biodegradability or recyclability, addressing crucial environmental concerns. Manufacturers are increasingly focusing on developing products that can be easily separated into their component materials for recycling or that naturally decompose without harmful environmental effects.

Innovation in this area continues to drive the development of more sustainable solutions, including compostable non-woven fabrics and materials designed for closed-loop recycling systems. These advancements demonstrate the industry's commitment to environmental stewardship while maintaining product performance.

Applications Across Industries

Medical and Healthcare Solutions

The medical sector has embraced non-woven fabrics for their exceptional properties in healthcare applications. These materials are essential components in surgical masks, gowns, drapes, and wound dressings. Their ability to provide bacterial barriers while maintaining breathability and comfort has made them indispensable in medical settings. The recent global health challenges have further highlighted the importance of non-woven fabrics in producing personal protective equipment (PPE).

Beyond immediate medical use, non-woven fabrics are finding applications in advanced wound care products and drug delivery systems. Their adaptable properties allow for the incorporation of antimicrobial agents and controlled-release medications, opening new possibilities in healthcare innovation.

Industrial and Technical Applications

The industrial sector leverages non-woven fabrics for their strength, durability, and specialized properties. From geotextiles in construction to filtration systems in manufacturing, these materials provide solutions to complex technical challenges. Their use in automotive interiors, building materials, and agricultural applications demonstrates their versatility and reliability in demanding environments.

The growing focus on sustainable infrastructure has created new opportunities for non-woven fabrics in green building materials and environmental protection applications. Their role in erosion control, soil stabilization, and water filtration systems showcases their importance in environmental engineering solutions.

Future Trends and Market Evolution

Technological Advancements

The future of non-woven fabrics is closely tied to technological innovation. Smart textiles incorporating sensors and responsive materials are emerging as a significant trend. These advanced materials can monitor environmental conditions, adapt to temperature changes, or even interact with digital devices. The integration of Internet of Things (IoT) technology with non-woven fabrics opens new possibilities for applications in healthcare monitoring and personal safety equipment.

Research into new fiber materials and production methods continues to push the boundaries of what's possible with non-woven fabrics. Developments in bioengineering and materials science are leading to fabrics with enhanced functionality and improved environmental profiles.

Market Growth and Economic Impact

The non-woven fabrics market is experiencing robust growth, driven by increasing demand across multiple sectors. Economic factors, including cost-effectiveness and production efficiency, continue to attract investment in non-woven technology. Market analysts project sustained growth as new applications emerge and existing markets expand.

Global events and changing consumer preferences are reshaping market dynamics, with increased emphasis on sustainable and locally produced materials. This trend is expected to drive further innovation and market development in the non-woven fabric industry.

Frequently Asked Questions

What makes non-woven fabrics different from traditional textiles?

Non-woven fabrics are created by bonding or interlocking fibers directly, bypassing the traditional spinning and weaving processes. This unique manufacturing method results in materials that can be engineered for specific properties and produced more efficiently than conventional textiles.

Are non-woven fabrics environmentally friendly?

Many non-woven fabrics are designed with environmental sustainability in mind, featuring reduced water and energy consumption during production, recyclable materials, and biodegradable options. However, the environmental impact varies depending on the specific materials and processes used.

What are the main applications of non-woven fabrics?

Non-woven fabrics find extensive use in medical supplies, personal care products, filtration systems, automotive components, construction materials, and agricultural applications. Their versatility allows them to be tailored for specific requirements across various industries.