textilis imprimatus extensibilis

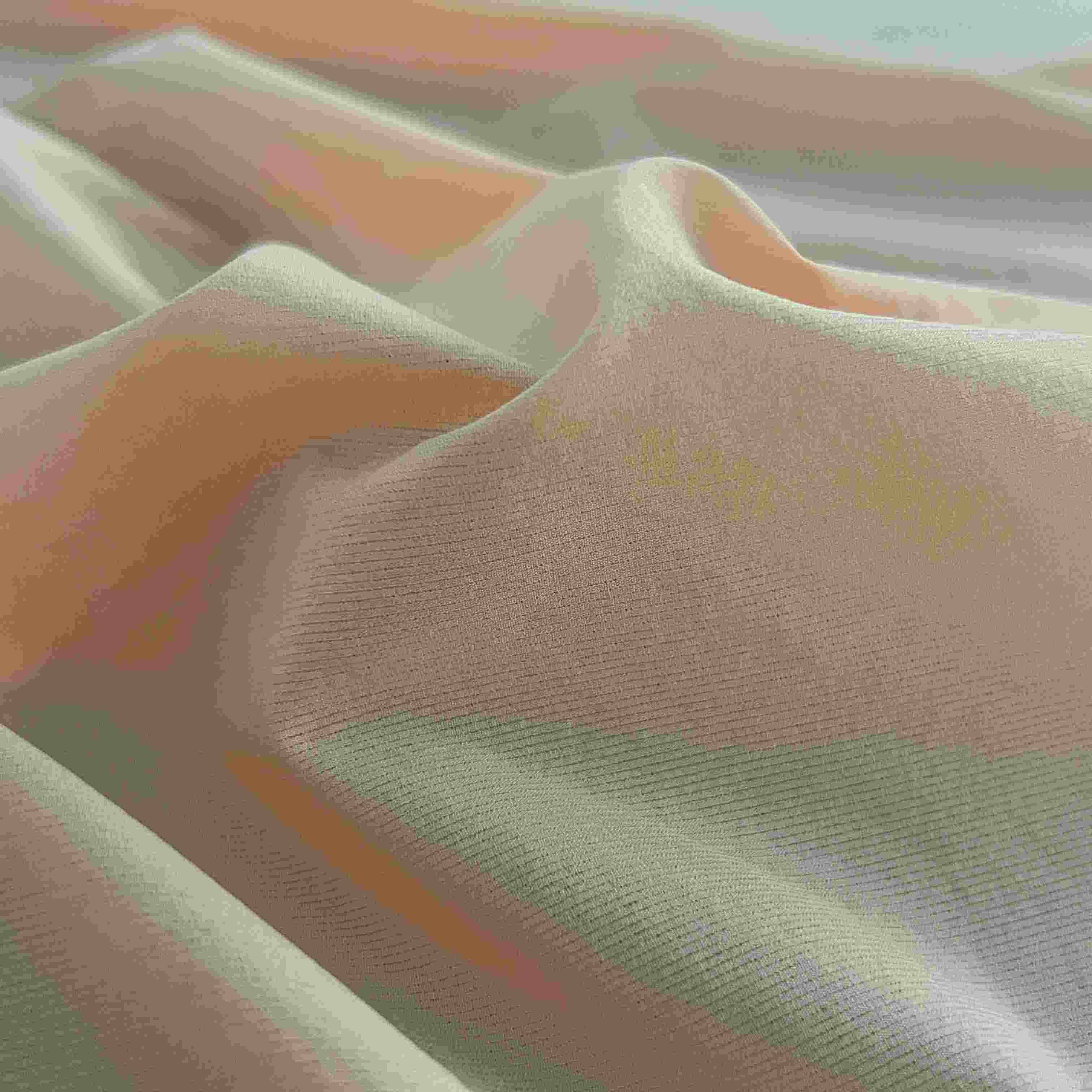

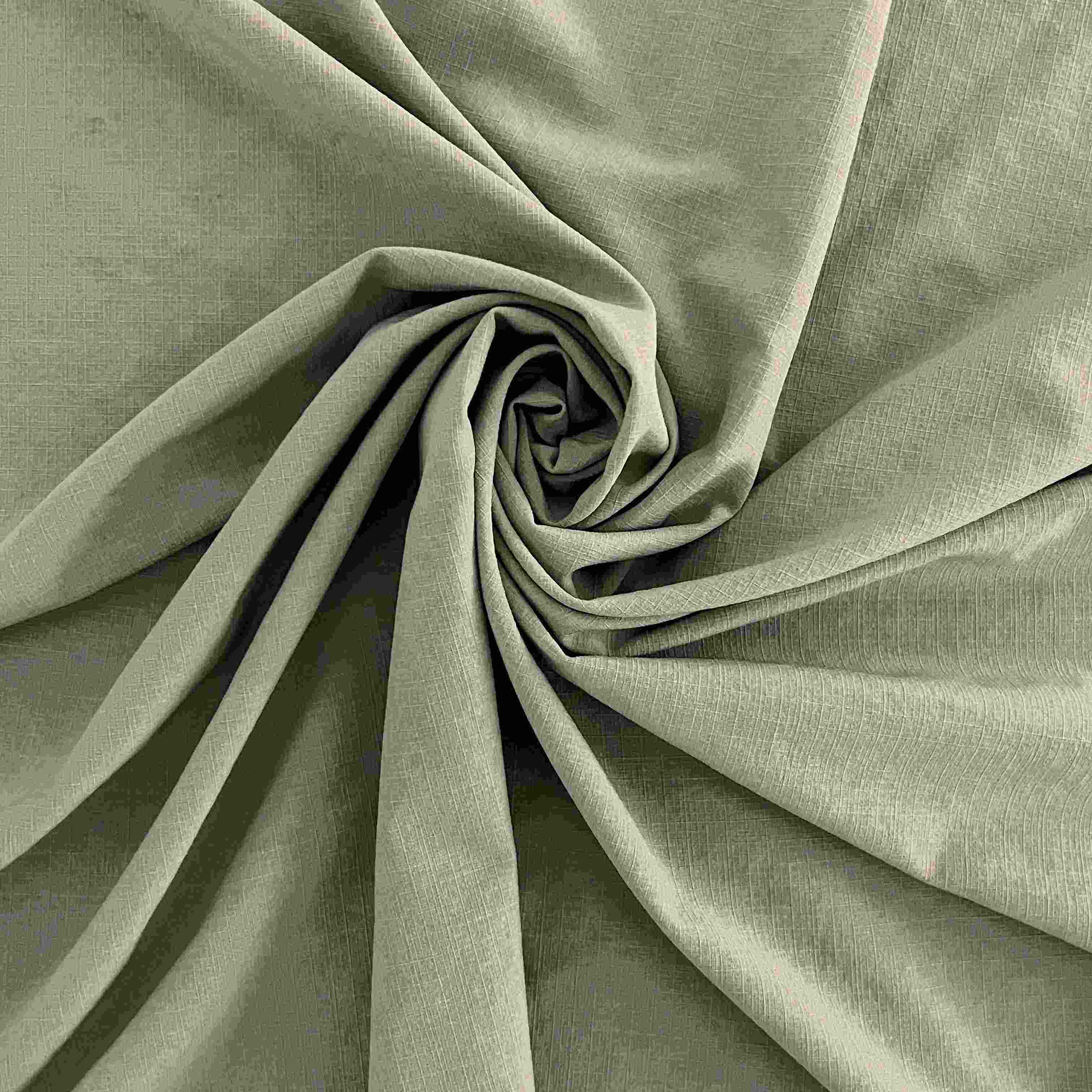

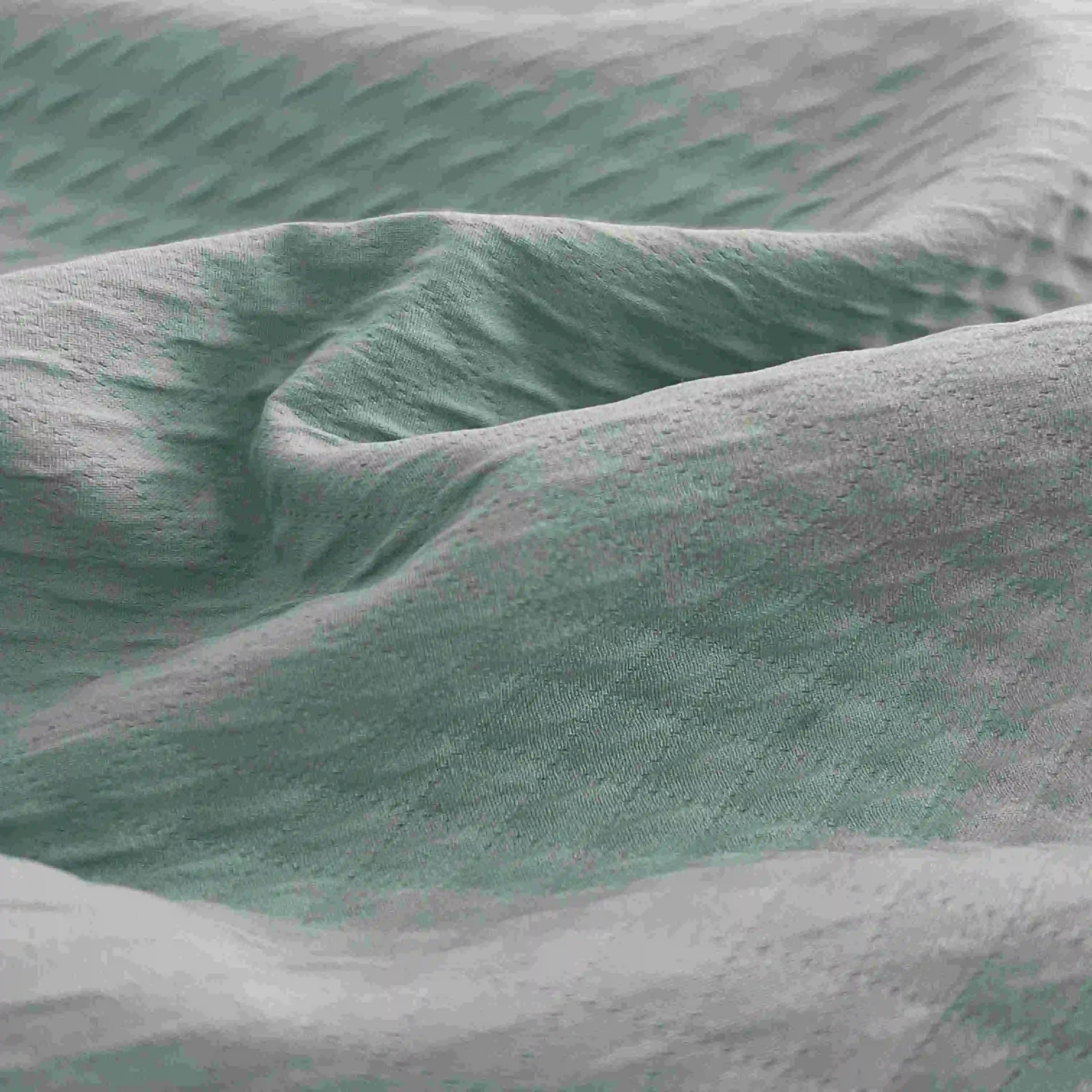

Tessutum impressum ex materia extensili indicat progressum revolutionarium in ingenio textilium, combinatoriam flexibilitatis cum aestheticis personalizabilibus. Hoc materiale innovativum continet compositionem unicum quod permittit elasticitatem praestantem dum servat designs impressos vividos et detailatos. Constructio tesseris communiter involvit mixtionem elastani aut spandex cum materialibus traditionalibus sicut polyestera vel bombicina, creans balancem perfectam inter capacitatem extensilem et durabilitatem. Processus imprimendi utitur technicis digitalibus aut rotariis praecipuis quae certificant fixitatem coloris et integritatem pattern etiam dum extenditur. Quod hoc materiale distinguit est facultas eius design claritatem et colorem vivacem conservare dum praebet motus exceptionales et proprietates recuperationis. Factor extensilis materiae potest variare ab 20% usque ultra 100%, secundum compositionem specificam et applicationem intentionatam. Haec tessera inveniunt usum extensum in vestibus athleticis, apparel fashion, choregis costumibus, et variis garmentis performance ubi ambo appeal aestheticus et functionalitas sunt cruciales. Processus manufacturae includit tractatus specialis qui meliores proprietates suffectivas et certificant designs impressos permanere per vestitus et lavationes repetitos.