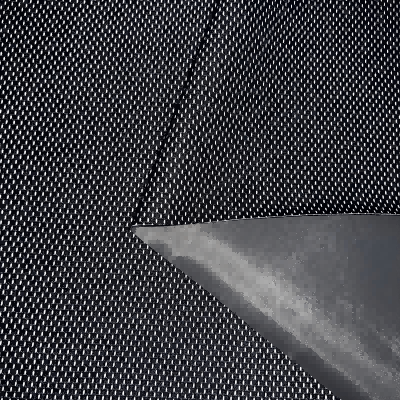

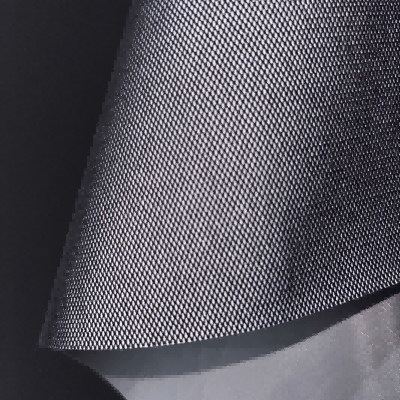

non woven fabric factory

A non woven fabric factory represents a cutting-edge manufacturing facility dedicated to producing versatile textile materials through innovative mechanical, thermal, or chemical processes. These facilities employ state-of-the-art machinery and advanced technologies to transform raw fibers directly into fabric, bypassing traditional spinning and weaving methods. The factory's production lines typically include specialized equipment for fiber preparation, web formation, web bonding, and finishing processes. Modern facilities integrate automated systems and quality control measures throughout the manufacturing process, ensuring consistent product quality and efficient production rates. The factory's capabilities extend to producing various fabric grades, from lightweight materials for medical applications to heavy-duty textiles for industrial use. Key technological features include precision control systems for fiber distribution, advanced bonding technologies such as needlepunching or spunlacing, and sophisticated finishing equipment for enhanced material properties. These facilities often incorporate sustainable practices, including energy-efficient systems and waste reduction measures. The factory's output serves diverse sectors, including medical, automotive, agriculture, and construction industries, providing customizable solutions for specific application requirements.