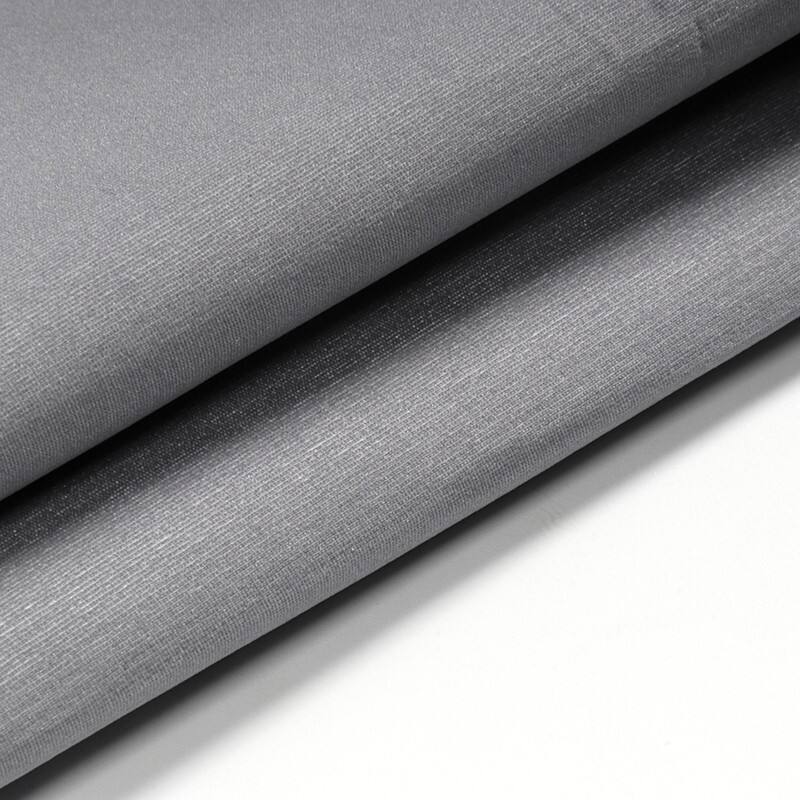

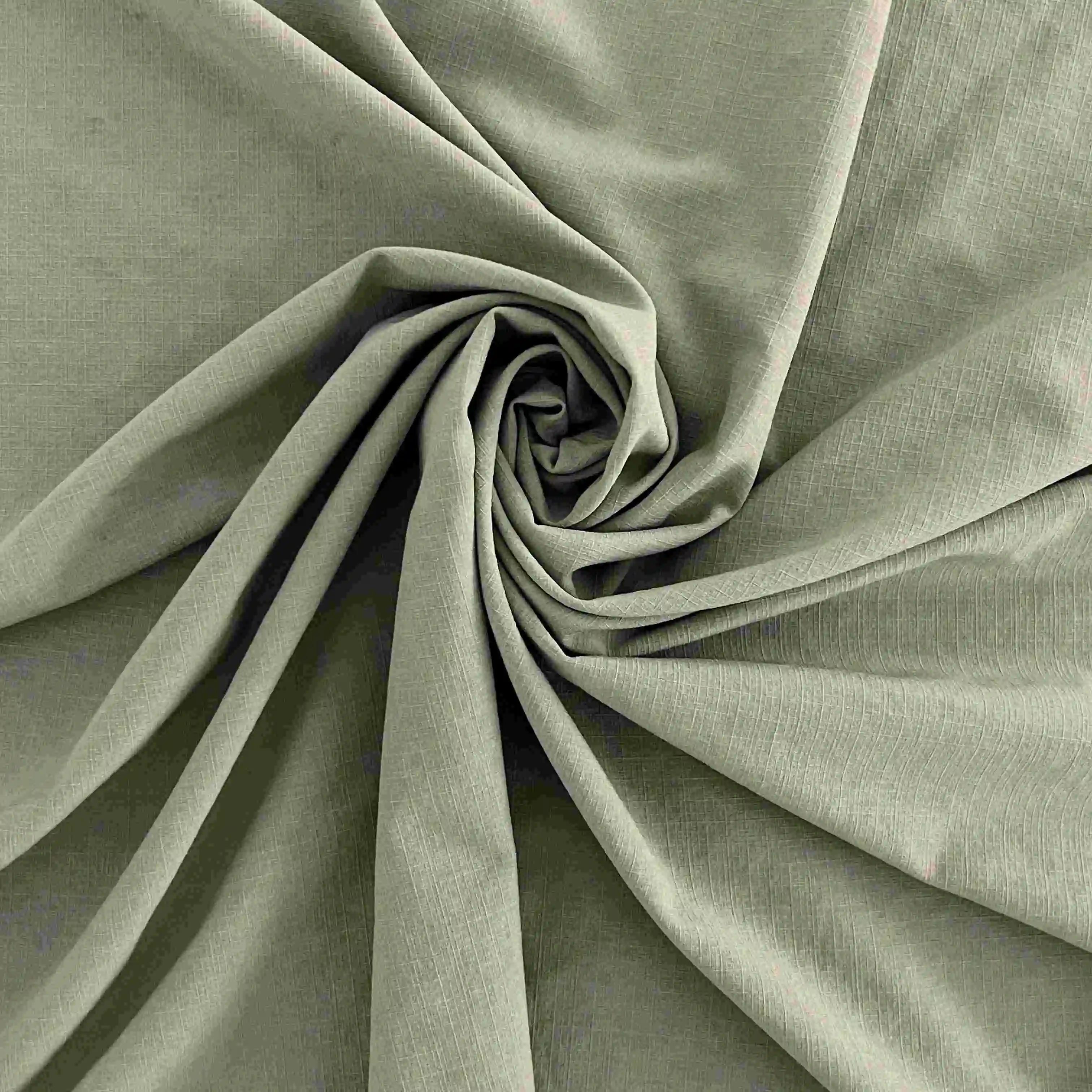

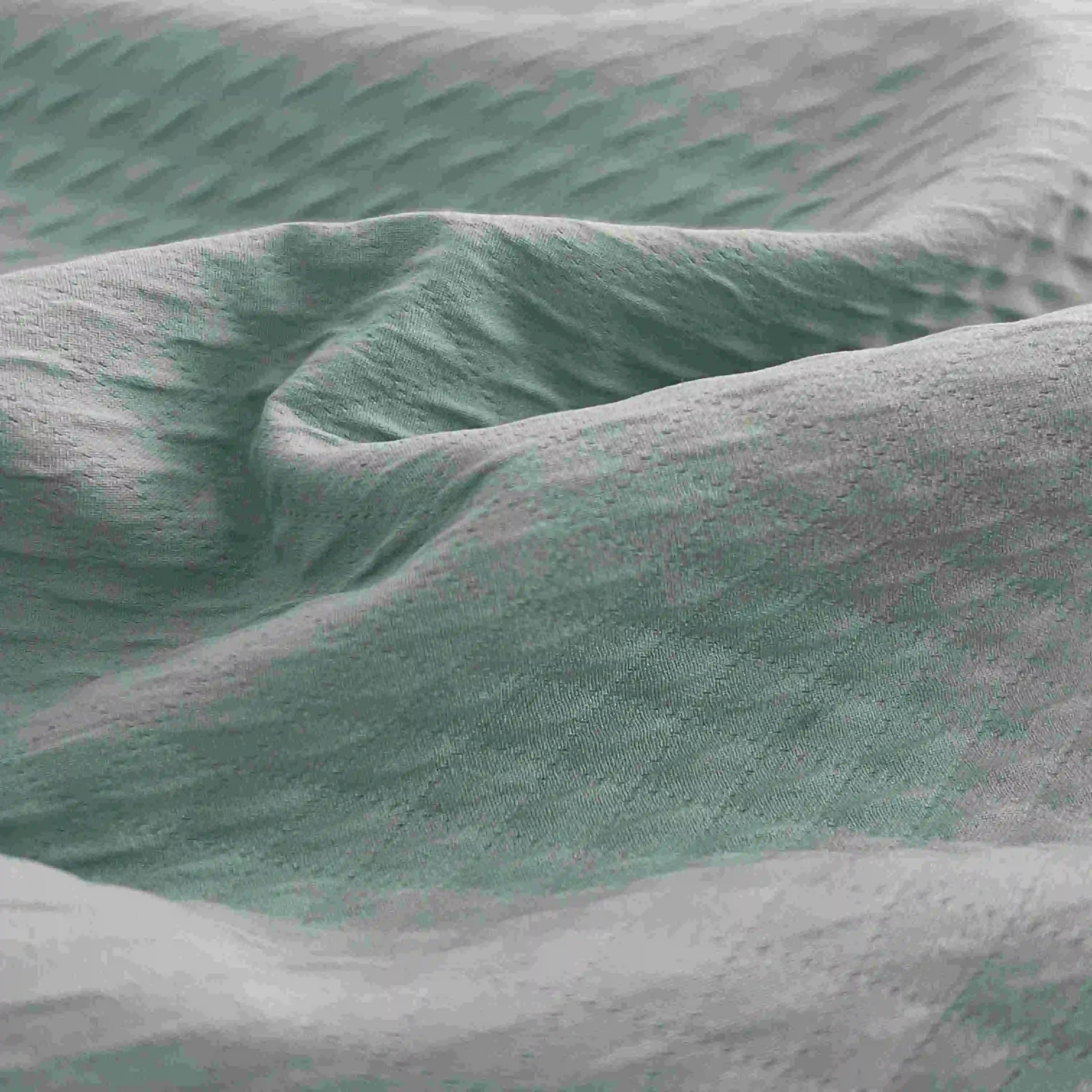

elastic non woven fabric

Elastic non woven fabric represents a revolutionary advancement in textile engineering, combining the versatility of non woven materials with enhanced elasticity. This innovative material is manufactured through a sophisticated process where elastic fibers are strategically integrated with traditional non woven structures, creating a fabric that offers exceptional stretch and recovery properties. The material's unique construction allows it to maintain structural integrity while providing superior flexibility and adaptability. The fabric features a distinctive combination of mechanical and thermal bonding techniques, resulting in a material that exhibits both strength and elasticity. Its primary functions include providing stretch comfort in medical supplies, personal care products, and hygiene applications. The technology behind elastic non woven fabric incorporates specialized fiber blending and advanced bonding methods, ensuring consistent performance across various applications. This material excels in applications requiring both conformability and strength, making it particularly valuable in medical bandages, disposable garments, and specialty cleaning products. The fabric's structure allows for excellent air permeability while maintaining necessary barrier properties, creating an optimal balance between protection and comfort. This versatile material has revolutionized various industries by offering a cost effective alternative to traditional elastic materials while maintaining superior performance characteristics.