non woven manufacturer

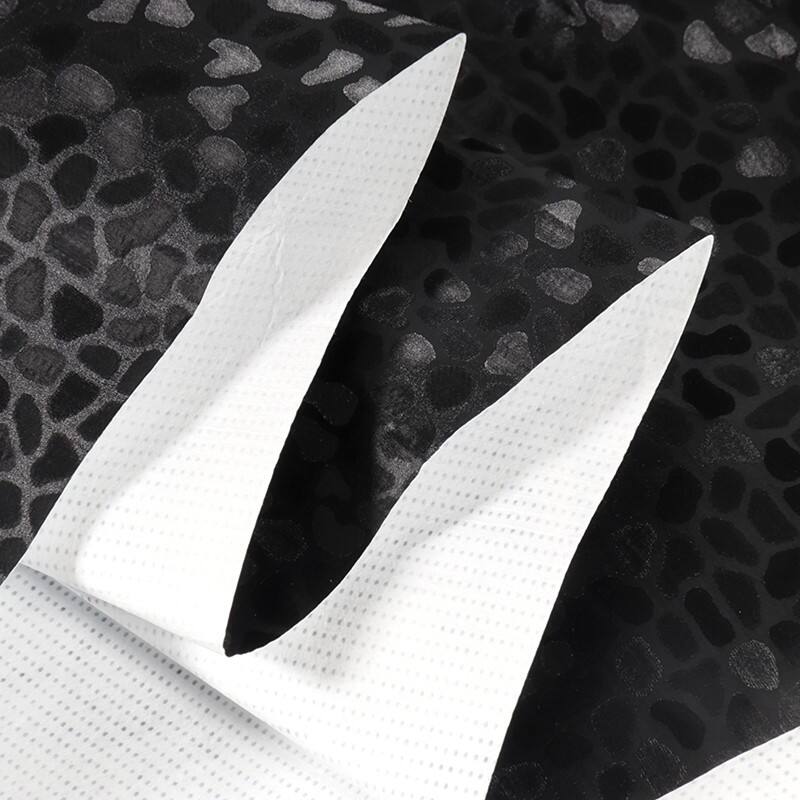

A non woven manufacturer represents a cornerstone in modern industrial textile production, specializing in the creation of unique fabric materials through mechanical, thermal, or chemical processes without traditional weaving or knitting. These facilities employ state of the art machinery and innovative technologies to produce materials that combine durability, versatility, and cost effectiveness. The manufacturing process involves carefully selected raw materials, primarily synthetic fibers like polypropylene, polyester, and rayon, which are bonded together using various techniques such as spunbonding, meltblowing, and needle punching. These advanced facilities maintain strict quality control measures throughout the production cycle, ensuring consistent product quality and meeting international standards. The manufacturer's capabilities typically extend to producing materials with specific properties such as liquid resistance, breathability, and varying degrees of strength. Their production lines are designed to accommodate both large scale industrial orders and specialized custom requirements, with the ability to adjust parameters like material thickness, density, and surface treatments according to client specifications. The facilities often integrate automated systems and real time monitoring to maintain precise control over production parameters, resulting in superior product consistency and reduced waste. Modern non woven manufacturers also emphasize sustainability, implementing eco friendly practices and developing recyclable products to meet growing environmental concerns.