Selecting the right outdoor fabric can make or break your project, whether you're designing outdoor furniture, creating protective covers, or manufacturing specialized equipment for harsh environments. The wrong choice leads to premature deterioration, costly replacements, and potential safety concerns. Understanding the key characteristics that define quality outdoor fabric ensures your investment delivers long-term performance and durability in challenging outdoor conditions.

Understanding Weather Resistance Properties

UV Protection and Fade Resistance

Ultraviolet radiation poses one of the greatest threats to outdoor fabric longevity. Quality materials incorporate UV-resistant treatments or inherent properties that prevent color degradation and structural breakdown. Solution-dyed fibers offer superior fade resistance compared to piece-dyed alternatives, maintaining vibrant colors even after years of direct sun exposure. The fabric's UV rating, typically measured in UPF (Ultraviolet Protection Factor), indicates its effectiveness in blocking harmful rays.

Professional-grade outdoor fabric often features specialized coatings or additives that enhance UV resistance without compromising breathability or flexibility. These treatments work at the molecular level, absorbing or reflecting UV radiation before it can damage the underlying fiber structure. Consider fabrics with UPF ratings of 30 or higher for applications requiring extended sun exposure, ensuring both material preservation and enhanced protection for underlying surfaces.

Water Resistance and Drainage

Effective water management goes beyond simple repellency. Premium outdoor fabric combines water-resistant surface treatments with strategic construction techniques that promote rapid drainage and prevent pooling. Hydrophobic coatings create a barrier against moisture penetration while maintaining the fabric's breathability, preventing the development of mold, mildew, and bacterial growth that can compromise both appearance and structural integrity.

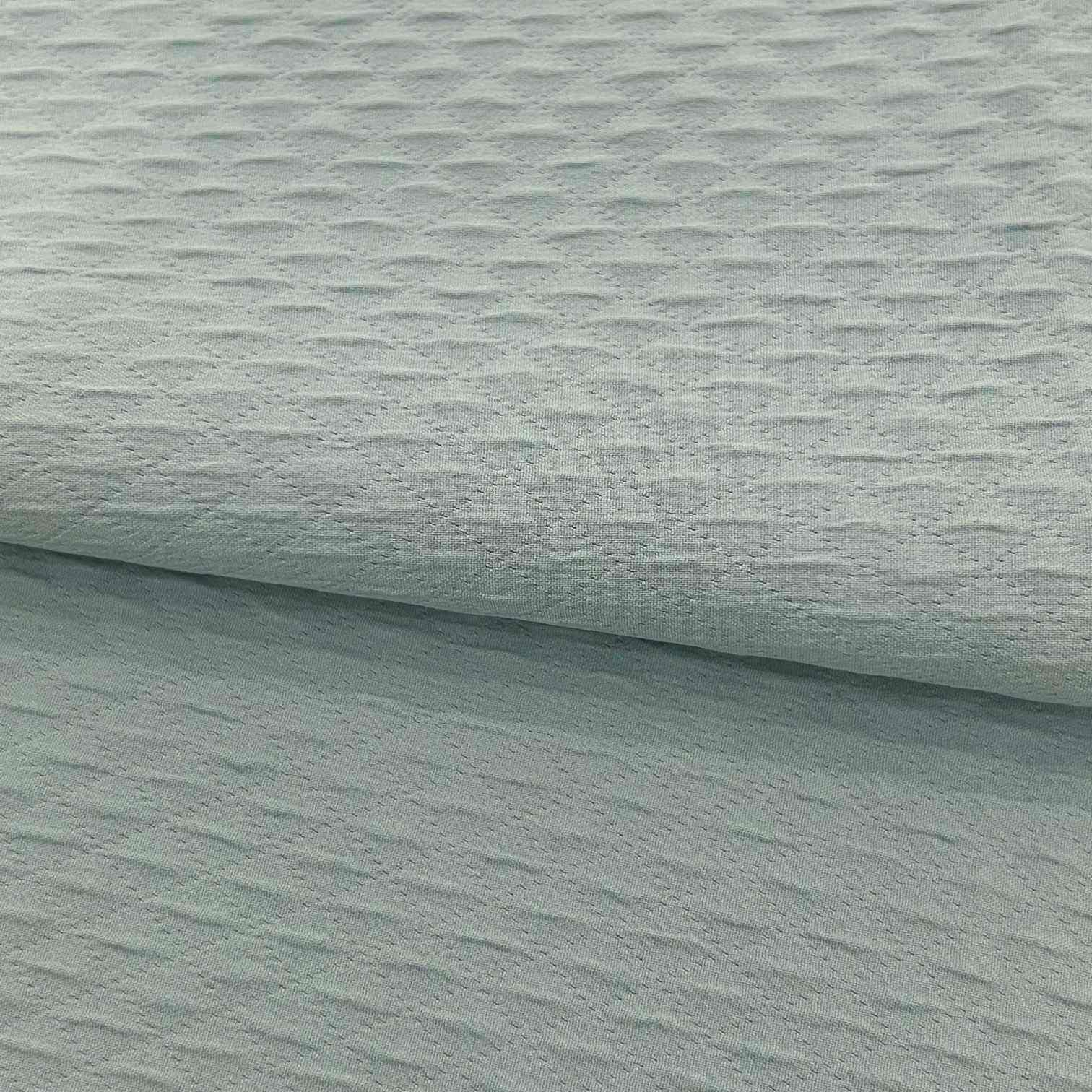

The fabric's weave structure plays a crucial role in water management. Tight weaves provide better initial water resistance, while slightly more open constructions facilitate air circulation and moisture evaporation. Many high-performance outdoor fabrics incorporate drainage channels or mesh backing systems that direct water away from the fabric surface, ensuring quick drying times and reducing the risk of water-related damage.

Material Construction and Durability Factors

Fiber Selection and Performance

The choice of base fiber significantly impacts an outdoor fabric's performance characteristics and lifespan. Acrylic fibers offer excellent color retention and weather resistance, making them popular for awnings and outdoor cushions. Polyester provides superior strength and abrasion resistance, ideal for heavy-duty applications. Vinyl-coated materials excel in extreme weather conditions, offering complete waterproofing and easy maintenance at the cost of reduced breathability.

Advanced synthetic blends combine multiple fiber types to achieve specific performance goals. These engineered fabrics might incorporate aramid fibers for enhanced tear resistance, microfibers for improved texture, or specialized polymer treatments for antimicrobial properties. The manufacturing process, including yarn twist, weave density, and finishing treatments, determines how effectively the fabric translates its raw material properties into real-world performance.

Strength and Tear Resistance

Outdoor environments subject fabrics to mechanical stresses that indoor materials never encounter. Wind loading, thermal expansion and contraction, and impacts from debris require outdoor fabric with exceptional tensile strength and tear resistance. The fabric's construction method, whether woven, knitted, or laminated, influences its ability to distribute stress and resist propagation of tears or punctures.

Professional specifications often include tear strength measurements in both warp and weft directions, indicating the fabric's resistance to ripping under load. Reinforcement techniques, such as ripstop construction or strategic placement of high-strength yarns, can significantly enhance durability without substantially increasing weight or cost. Consider applications requiring frequent handling, installation, or exposure to sharp objects when evaluating tear resistance requirements.

Environmental Compatibility and Maintenance

Temperature Extremes and Flexibility

Outdoor fabric must maintain its performance characteristics across wide temperature ranges. Cold temperatures can make some materials brittle and prone to cracking, while excessive heat can cause softening, dimensional changes, or degradation of coatings. Quality outdoor fabrics incorporate plasticizers or flexible polymer chains that preserve pliability in cold conditions while maintaining structural integrity in heat.

Thermal cycling, the repeated expansion and contraction caused by temperature fluctuations, creates stress that can lead to premature failure. Fabrics designed for outdoor use often feature construction techniques that accommodate dimensional changes without compromising seams or surface treatments. Understanding your specific climate conditions helps determine the temperature range requirements for optimal fabric selection.

Cleaning and Maintenance Requirements

Maintenance accessibility directly impacts the long-term cost-effectiveness of outdoor fabric installations. Easy-care fabrics with stain-resistant treatments reduce cleaning frequency and simplify maintenance procedures. Some outdoor fabric can be cleaned with simple soap and water, while others require specialized cleaning agents or professional services to maintain their protective treatments.

Consider the cleaning method compatibility with your maintenance schedule and resources. Fabrics that can withstand pressure washing offer convenience for large installations, while delicate materials might require gentle hand cleaning. The frequency of required maintenance, seasonal care procedures, and the availability of cleaning supplies or services should factor into your selection process to ensure realistic long-term maintenance planning.

Application-Specific Selection Criteria

Structural vs. Decorative Applications

The intended use significantly influences outdoor fabric selection priorities. Structural applications, such as shade sails, awnings, or architectural membranes, prioritize strength, wind resistance, and dimensional stability over aesthetic considerations. These applications require fabrics with high tensile strength, low stretch characteristics, and proven performance in challenging weather conditions.

Decorative applications allow more flexibility in prioritizing appearance, texture, and color options while still maintaining adequate weather resistance. Outdoor furniture cushions, decorative covers, and accent pieces can utilize fabrics with enhanced comfort characteristics or unique visual properties, provided they meet basic durability requirements for their specific exposure level.

Installation and Fabrication Considerations

The fabric's behavior during cutting, sewing, and installation affects both initial project costs and long-term performance. Some outdoor fabric requires specialized equipment or techniques for proper fabrication, including heat sealing, welding, or reinforced seaming methods. Consider the availability of qualified fabricators and installation teams when selecting advanced materials that require specific expertise.

Edge finishing requirements vary significantly among different fabric types. Some materials fray easily and require bound edges or welded seams, while others maintain clean cut edges without additional finishing. Understanding fabrication requirements early in the selection process prevents unexpected costs and ensures compatibility with available installation methods and timelines.

FAQ

How long does quality outdoor fabric typically last

Quality outdoor fabric typically lasts between 5 to 15 years depending on the material type, manufacturing quality, and exposure conditions. Premium acrylic fabrics often provide 10-15 years of service life, while vinyl-coated materials may last 5-10 years. Factors such as UV exposure intensity, temperature extremes, and maintenance frequency significantly impact longevity. Regular cleaning and proper installation can extend fabric life substantially beyond minimum expectations.

What is the difference between water-resistant and waterproof outdoor fabric

Water-resistant outdoor fabric repels light to moderate moisture but may eventually allow water penetration under prolonged exposure or pressure. Waterproof fabrics create a complete barrier against water penetration regardless of exposure duration or pressure levels. Water-resistant materials typically maintain better breathability and flexibility, while waterproof options sacrifice some comfort for complete moisture protection. Choose based on your specific moisture exposure requirements and ventilation needs.

Can outdoor fabric be repaired if damaged

Most outdoor fabric can be repaired using appropriate patching materials and techniques. Small tears or punctures often respond well to adhesive patches or sewn repairs using compatible thread and reinforcement materials. However, extensive damage, UV degradation, or coating failure typically requires fabric replacement rather than repair. Professional assessment helps determine whether repair is cost-effective compared to replacement, considering both immediate costs and long-term performance expectations.

How do I determine the right weight outdoor fabric for my project

Fabric weight selection depends on structural requirements, wind exposure, and installation method. Lightweight fabrics (4-8 oz per square yard) suit decorative applications with minimal structural demands. Medium weights (8-12 oz) work well for standard awnings and moderate wind conditions. Heavy-duty applications require 12+ oz fabrics for maximum durability and wind resistance. Consider consulting with fabric suppliers or structural engineers for high-stress applications to ensure adequate safety margins.