spunbond non woven fabric manufacturer

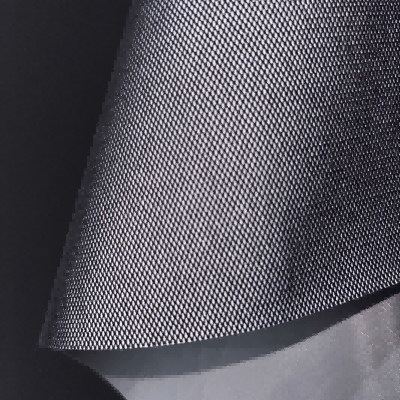

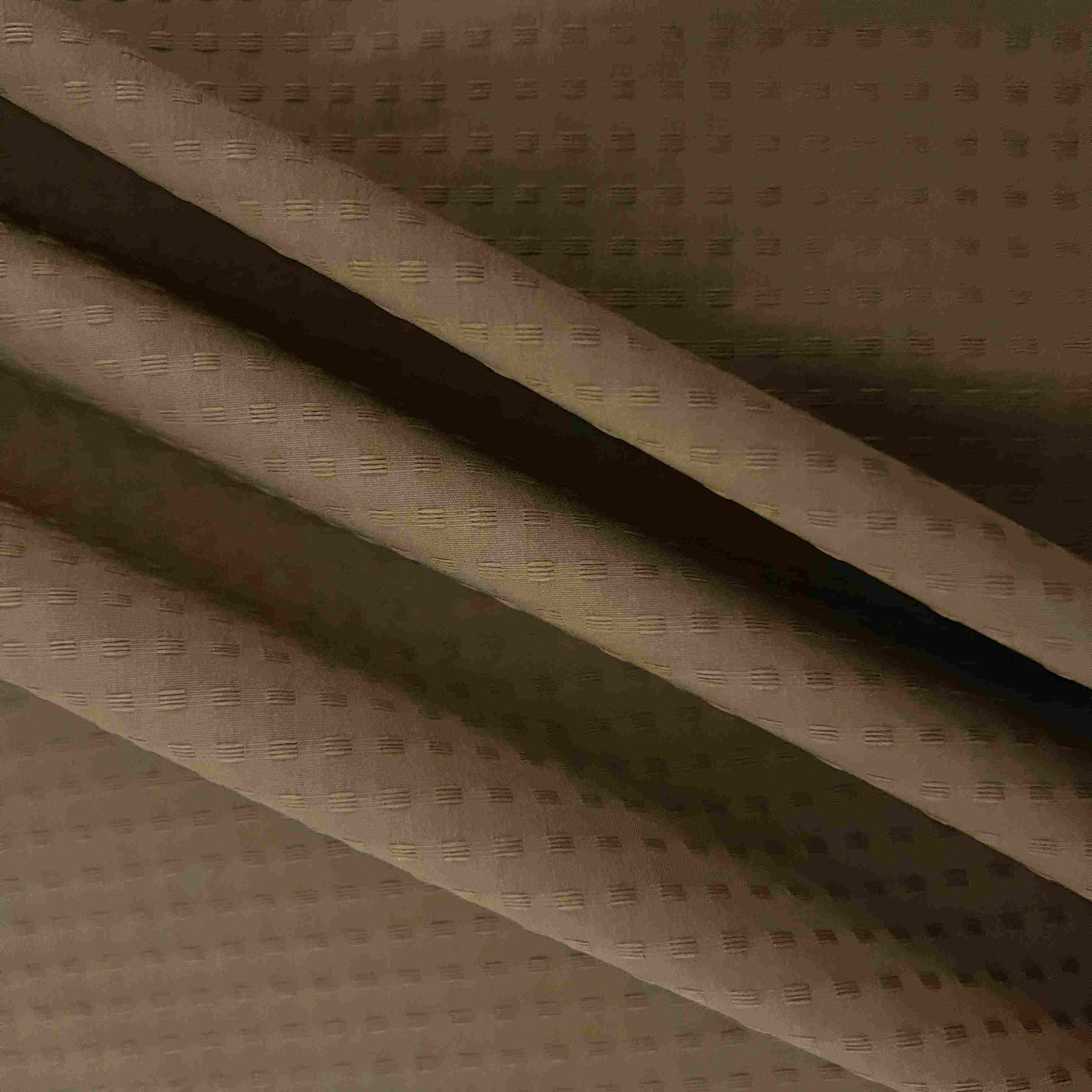

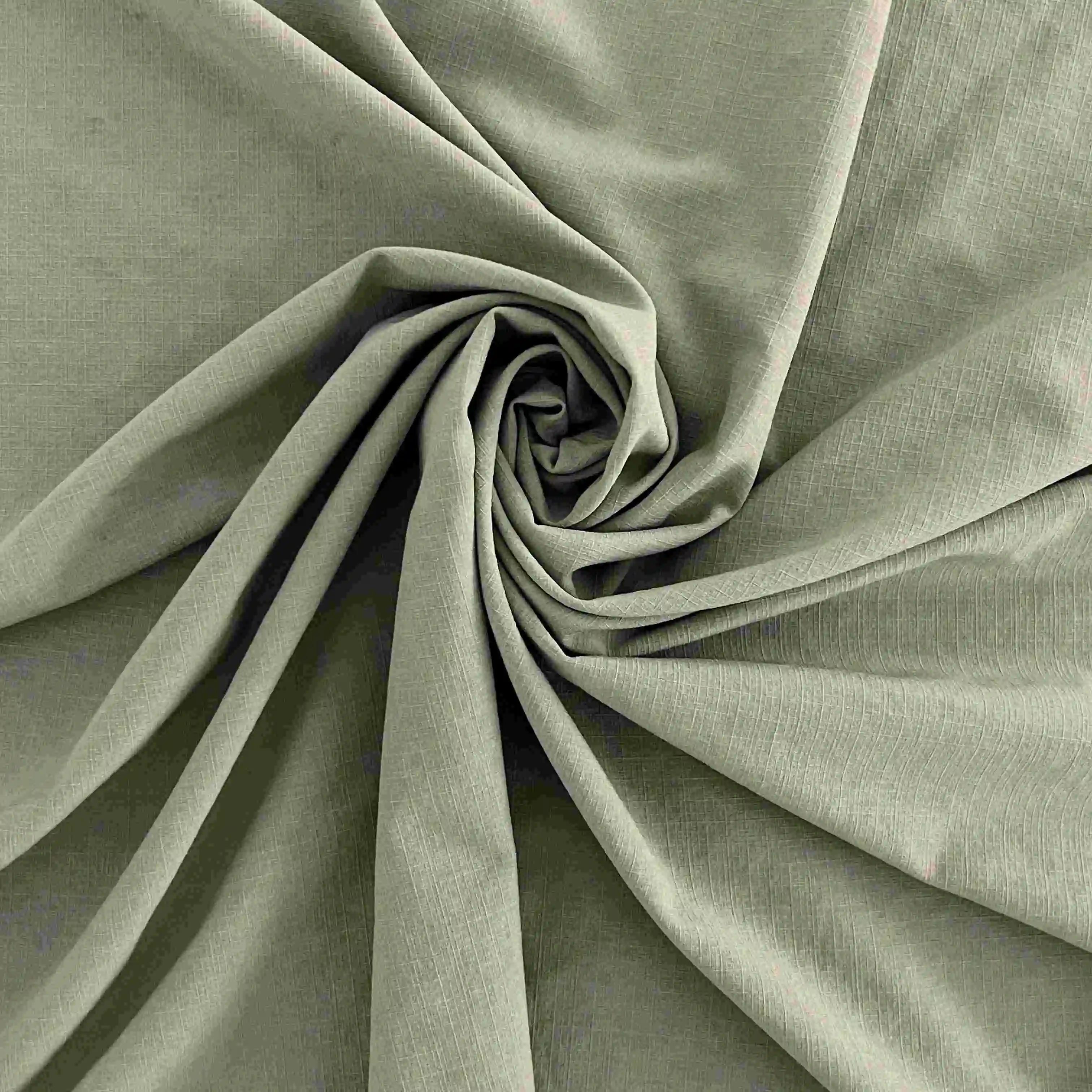

A spunbond non woven fabric manufacturer represents a cornerstone in modern textile production, specializing in creating versatile materials through an advanced continuous filament process. These facilities employ state of the art technology to transform polymer granules, typically polypropylene, into high quality non woven textiles through extrusion, spinning, and bonding processes. The manufacturing process begins with the melting of polymer chips, which are then extruded through specialized spinnerets to create continuous filaments. These filaments undergo controlled cooling before being laid on a forming belt in a random orientation, creating a uniform web structure. The web is then bonded using various techniques, including thermal, chemical, or mechanical methods, resulting in a fabric with specific physical properties. These manufacturers implement rigorous quality control systems, ensuring consistent product characteristics such as tensile strength, elongation, and uniformity. Modern facilities often integrate automated production lines with real time monitoring systems, allowing for precise control over fabric weight, thickness, and other critical parameters. The resulting materials find applications across diverse sectors, including medical supplies, agriculture, automotive, construction, and hygiene products, showcasing the manufacturer's ability to meet varied industry demands.