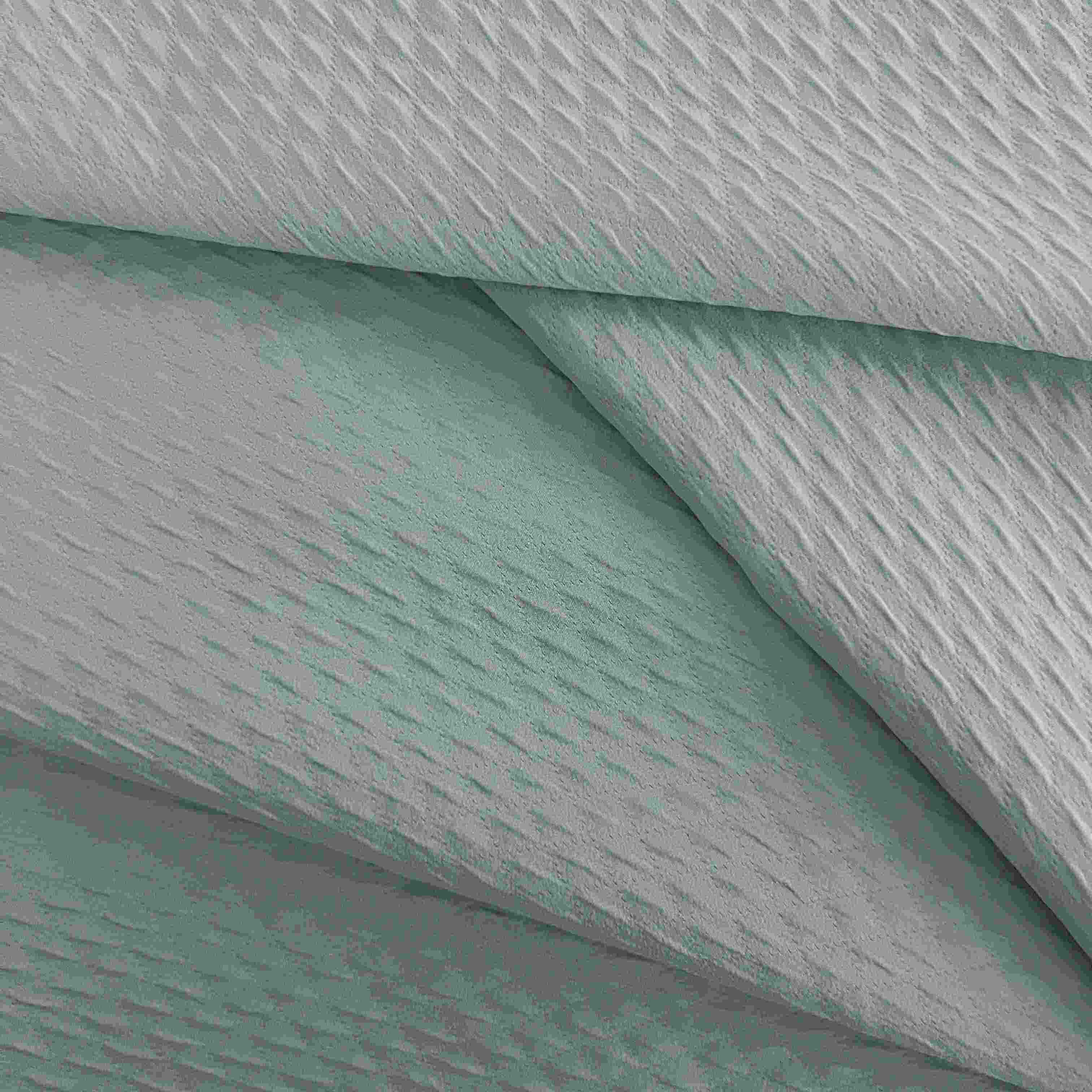

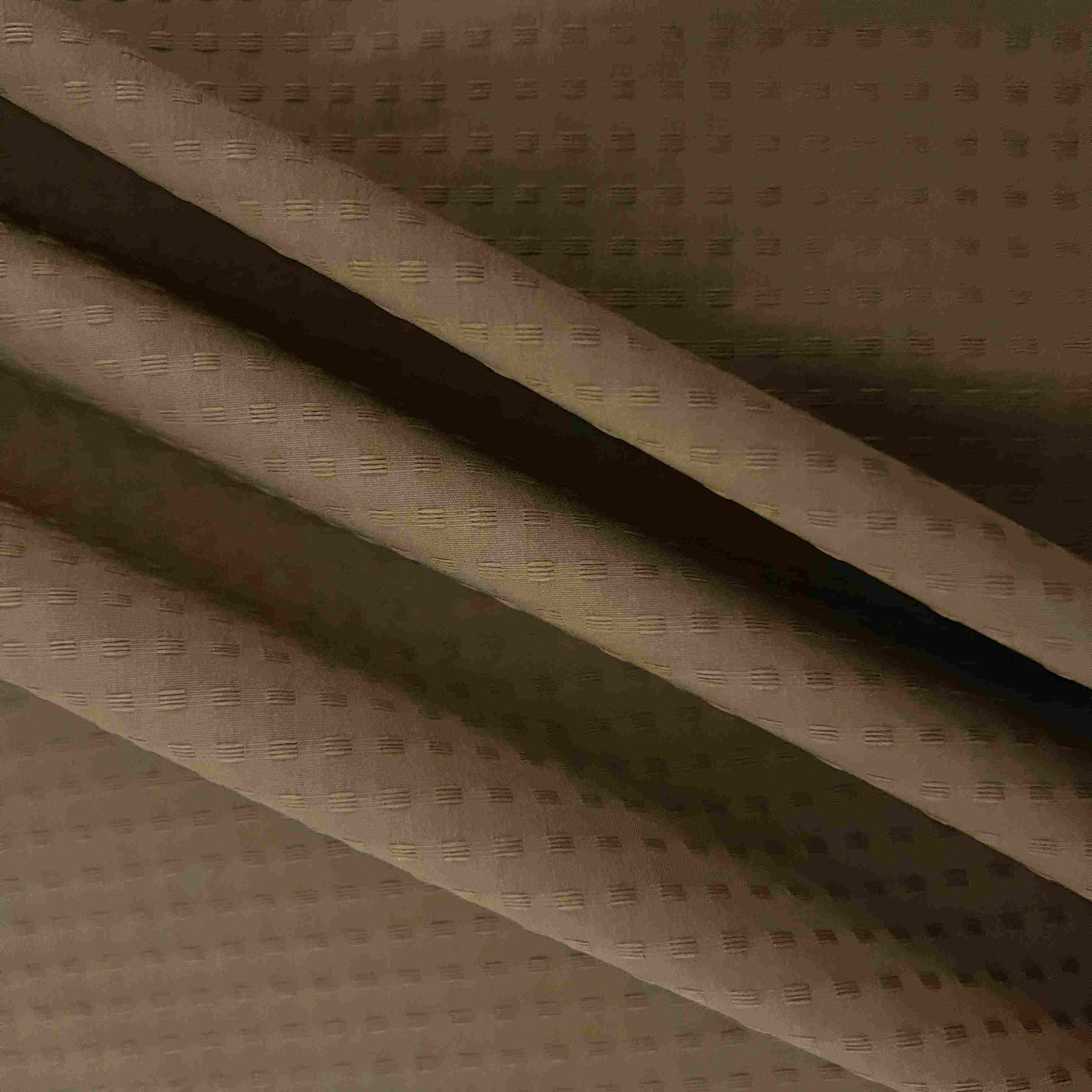

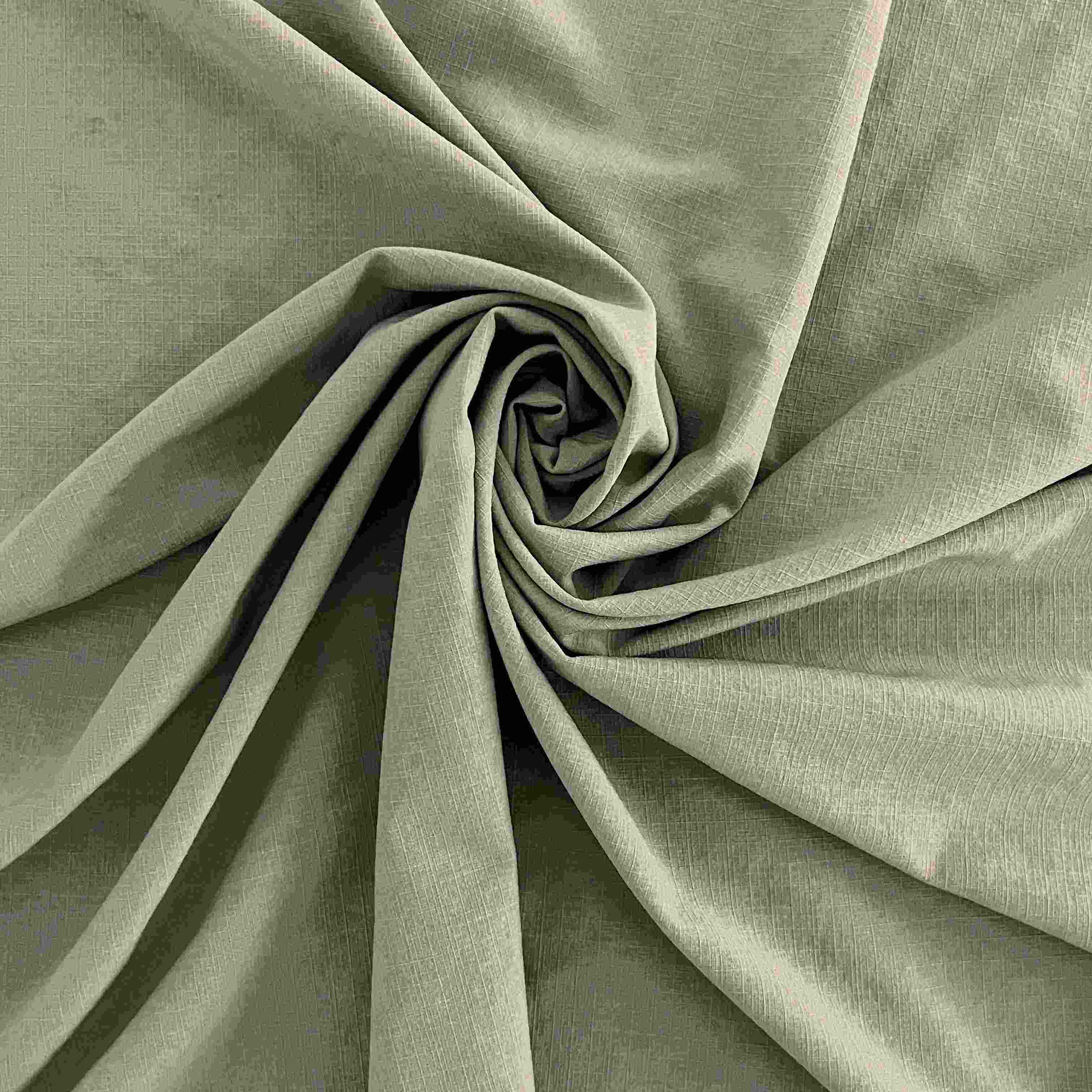

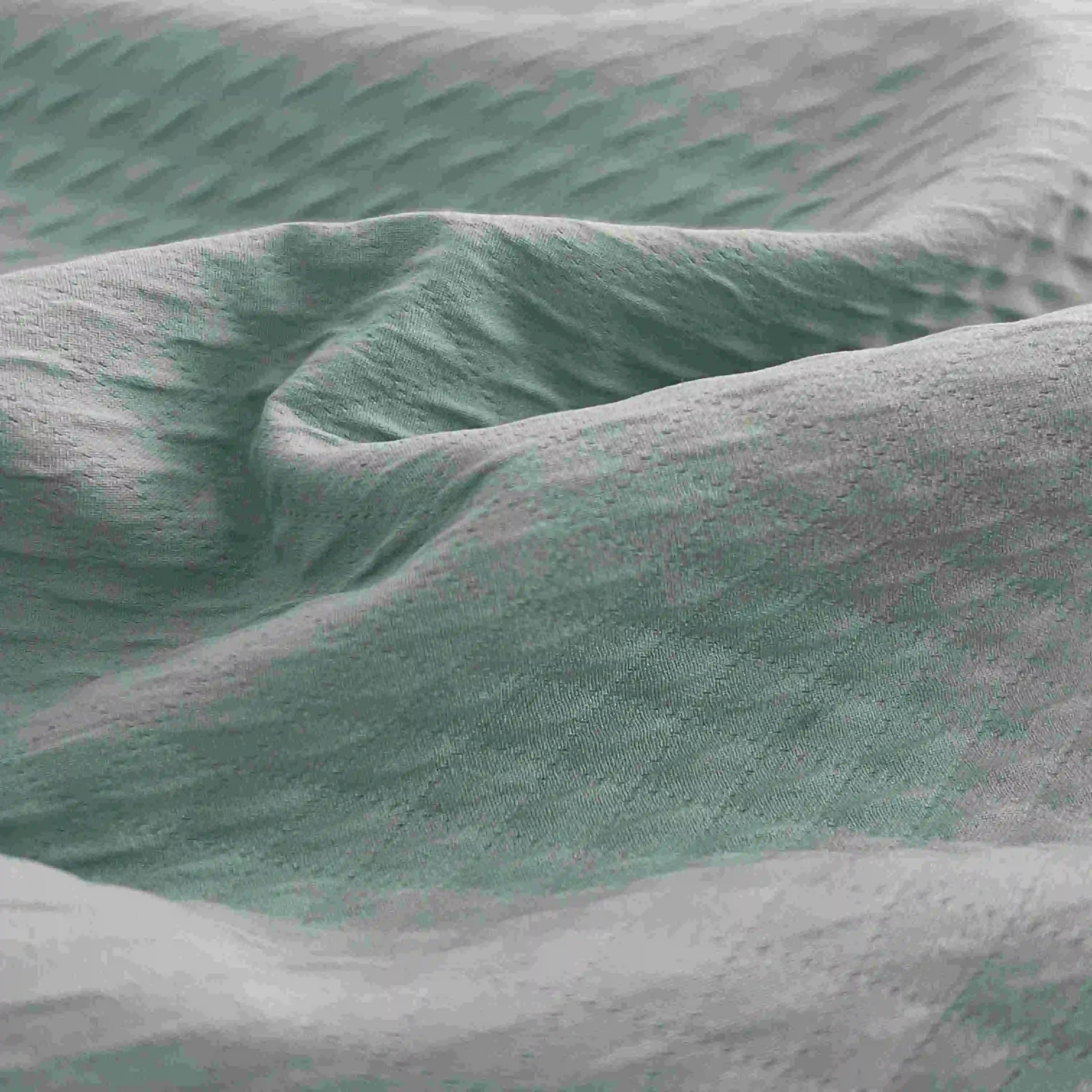

non woven fabric for sale

Non woven fabric represents a revolutionary material in the textile industry, engineered through advanced manufacturing processes that bond fibers together without traditional weaving or knitting. This versatile material offers exceptional durability, flexibility, and cost effectiveness for various applications. Our premium non woven fabric features superior tensile strength and uniform thickness, achieved through state of the art spunbond and meltblown technologies. The fabric demonstrates remarkable absorbency and filtration capabilities, making it ideal for medical supplies, filtration systems, and protective equipment. Its unique manufacturing process allows for customizable properties, including bacterial resistance, water repellency, and UV protection. The material excels in both disposable and reusable applications, providing excellent breathability while maintaining structural integrity. Available in various weights, widths, and colors, our non woven fabric meets diverse industry requirements, from automotive and agriculture to construction and healthcare sectors.