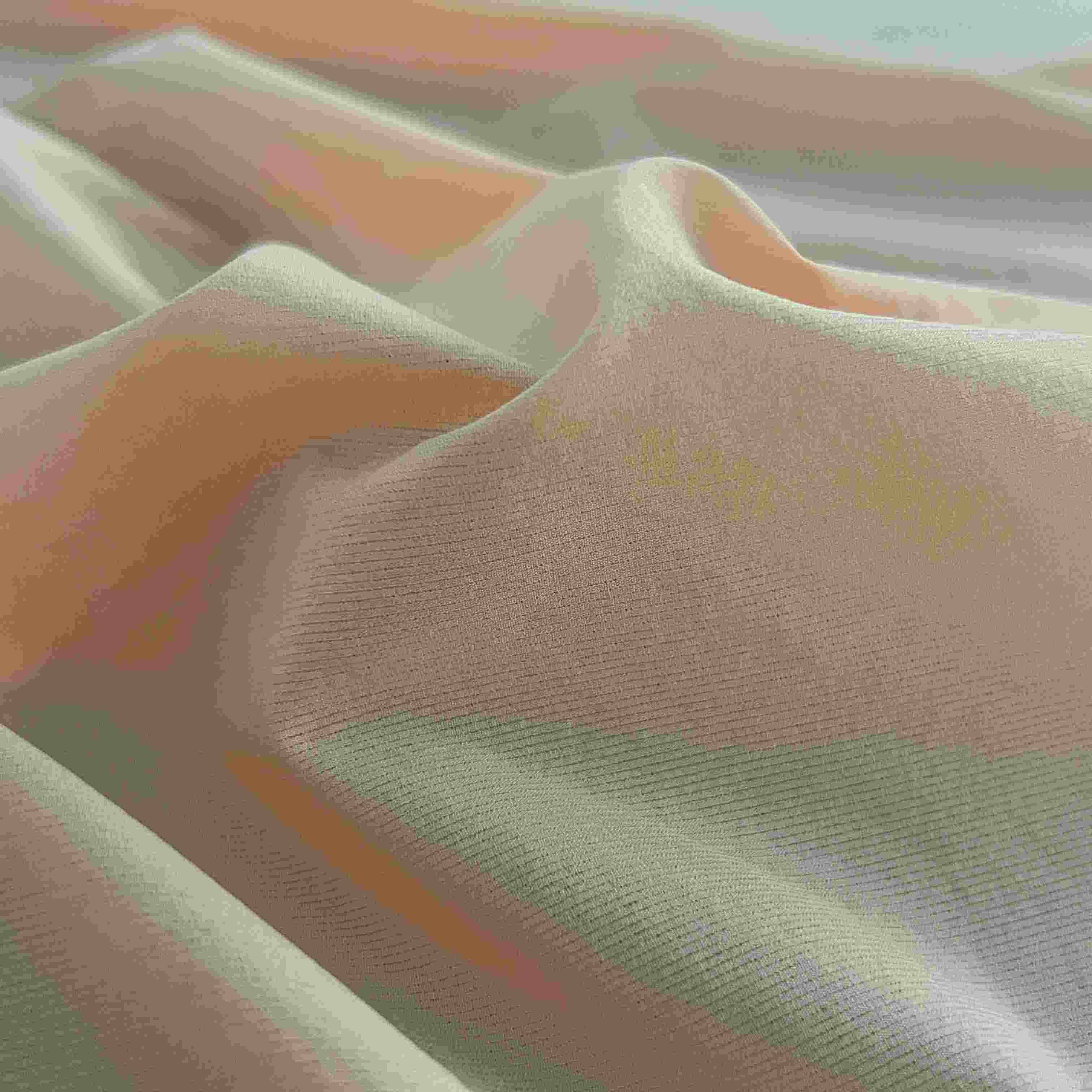

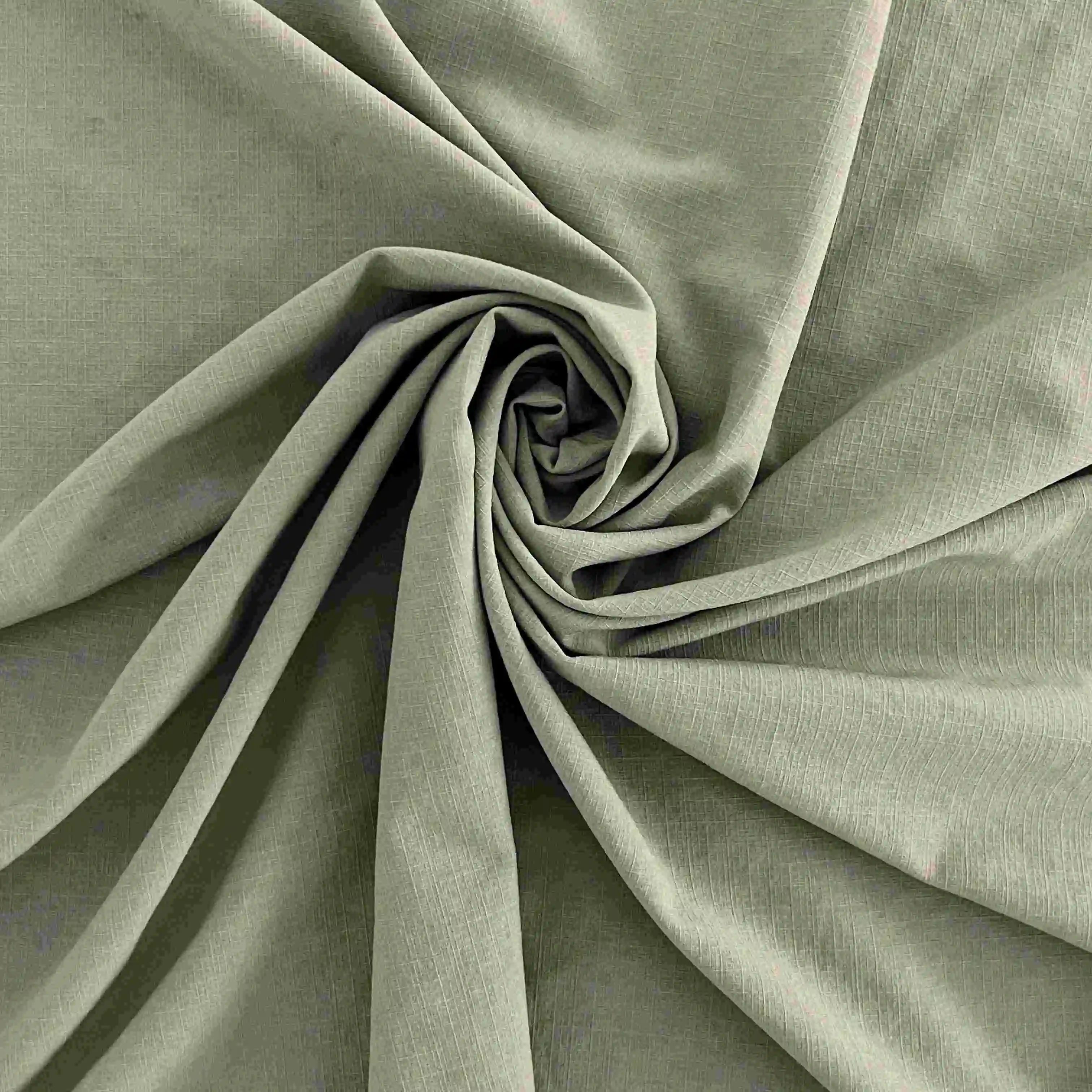

non woven fabric raw material

Non woven fabric raw material represents a revolutionary advancement in textile manufacturing, serving as the foundation for producing versatile and high performance materials. This engineered material consists primarily of polypropylene, polyester, or natural fibers that are bonded together through mechanical, thermal, or chemical processes rather than traditional weaving or knitting methods. The raw material's structure allows for exceptional customization in terms of thickness, density, and surface properties, making it ideal for diverse applications across multiple industries. The material's unique manufacturing process enables the creation of fabrics with specific characteristics such as high strength, excellent durability, superior filtration capabilities, and enhanced absorption properties. In industrial applications, these raw materials are processed to create filtration systems, geotextiles, and protective equipment. The medical sector utilizes these materials for surgical masks, gowns, and sterilization wraps, benefiting from their bacterial barrier properties and cost effectiveness. In the automotive industry, non woven fabrics derived from these raw materials are essential components in vehicle interiors, providing sound insulation and structural support. The construction sector employs these materials for insulation, waterproofing, and soil stabilization purposes. The versatility of non woven fabric raw materials extends to consumer goods, where they are used in products ranging from household cleaning wipes to agricultural covers.