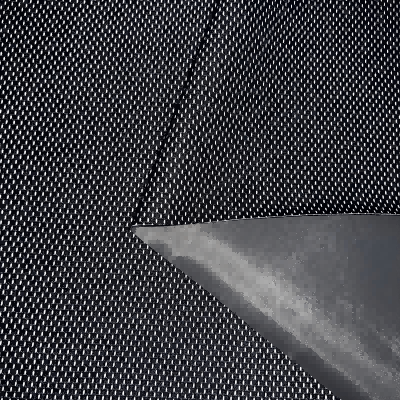

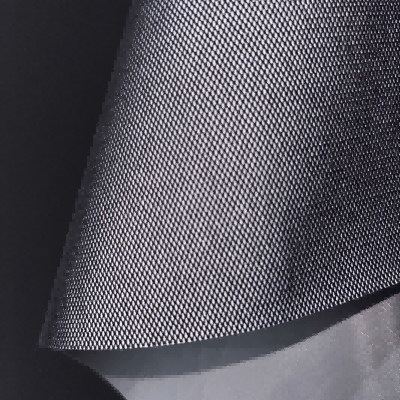

non woven fabric price

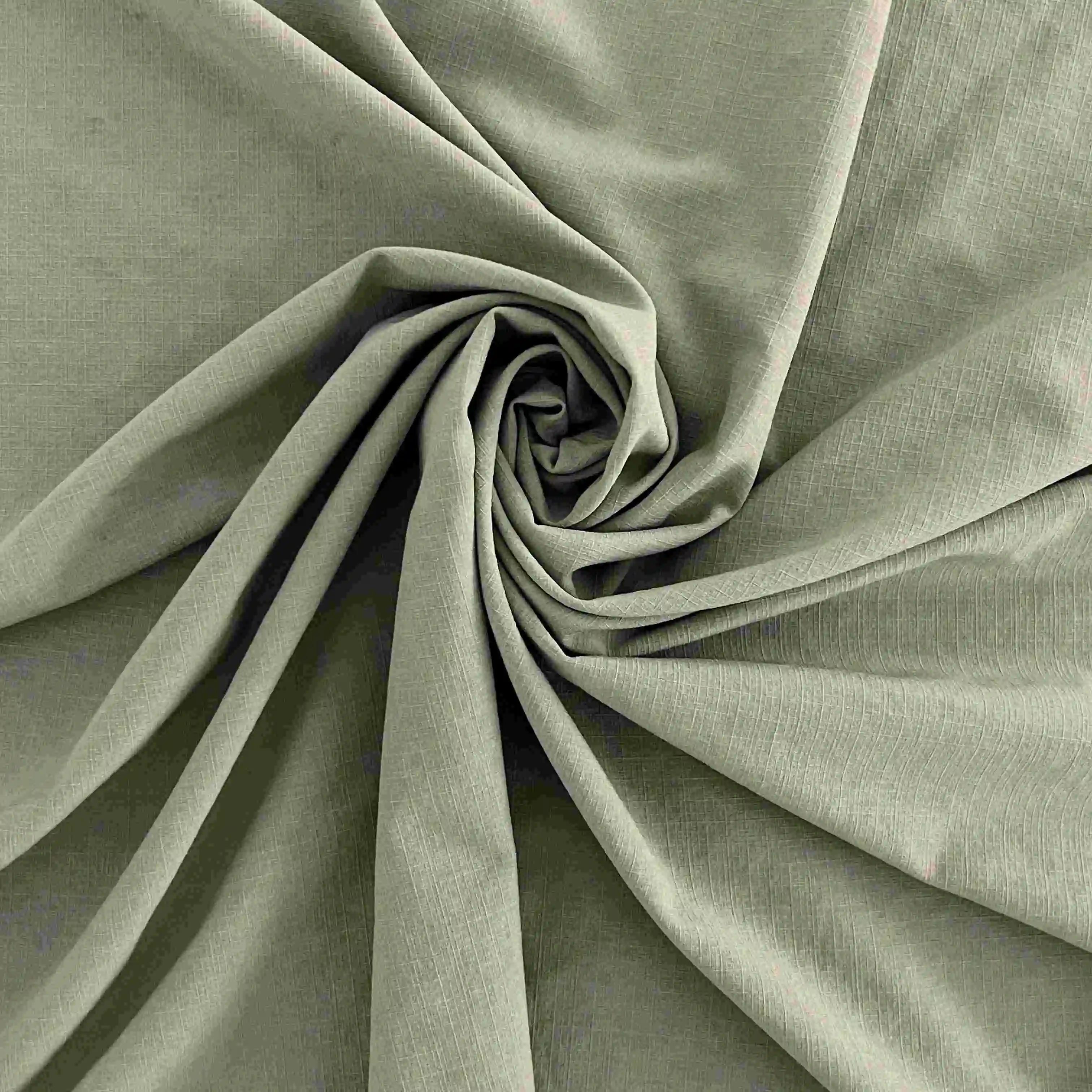

Non woven fabric price represents a crucial factor in the textile industry, reflecting the intersection of quality, manufacturing processes, and market demand. This versatile material, produced through bonding or interlocking fibers mechanically, chemically, or thermally, offers cost-effective solutions across various applications. The pricing structure typically varies based on factors such as material composition, weight per square meter, production volume, and specific technical requirements. Current market trends show prices ranging from $0.50 to $5.00 per square meter, depending on quality grades and specifications. The manufacturing process, utilizing advanced technologies like spunbond, meltblown, or needle punch methods, significantly influences the final cost. These materials find extensive use in medical supplies, agricultural covering, packaging, automotive interiors, and disposable hygiene products. The price point also reflects the material's durability, breathability, and filtration capabilities, making it an economical choice for both industrial and consumer applications. Market dynamics, raw material costs, and production efficiency continue to shape pricing strategies in this sector.