printed non woven fabric

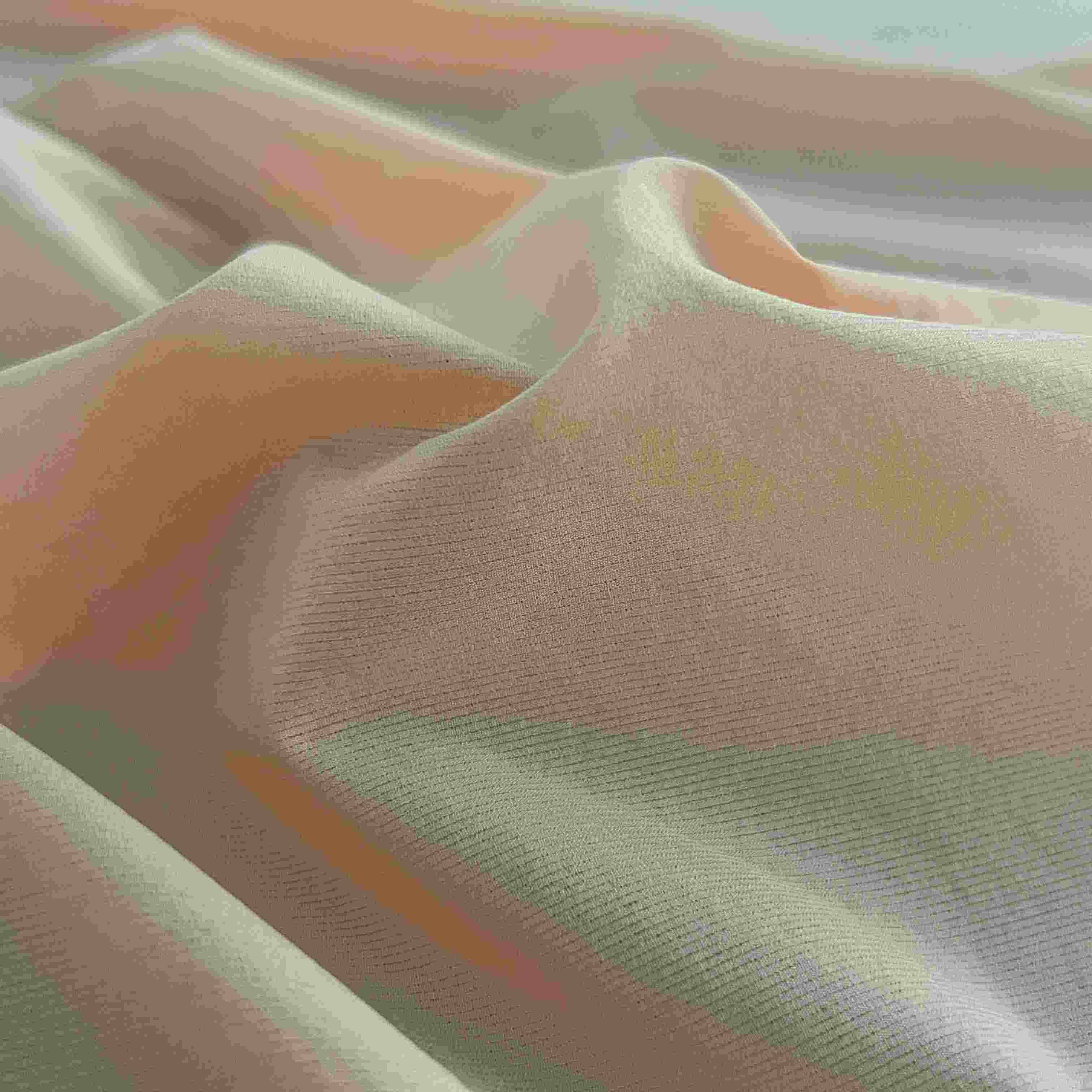

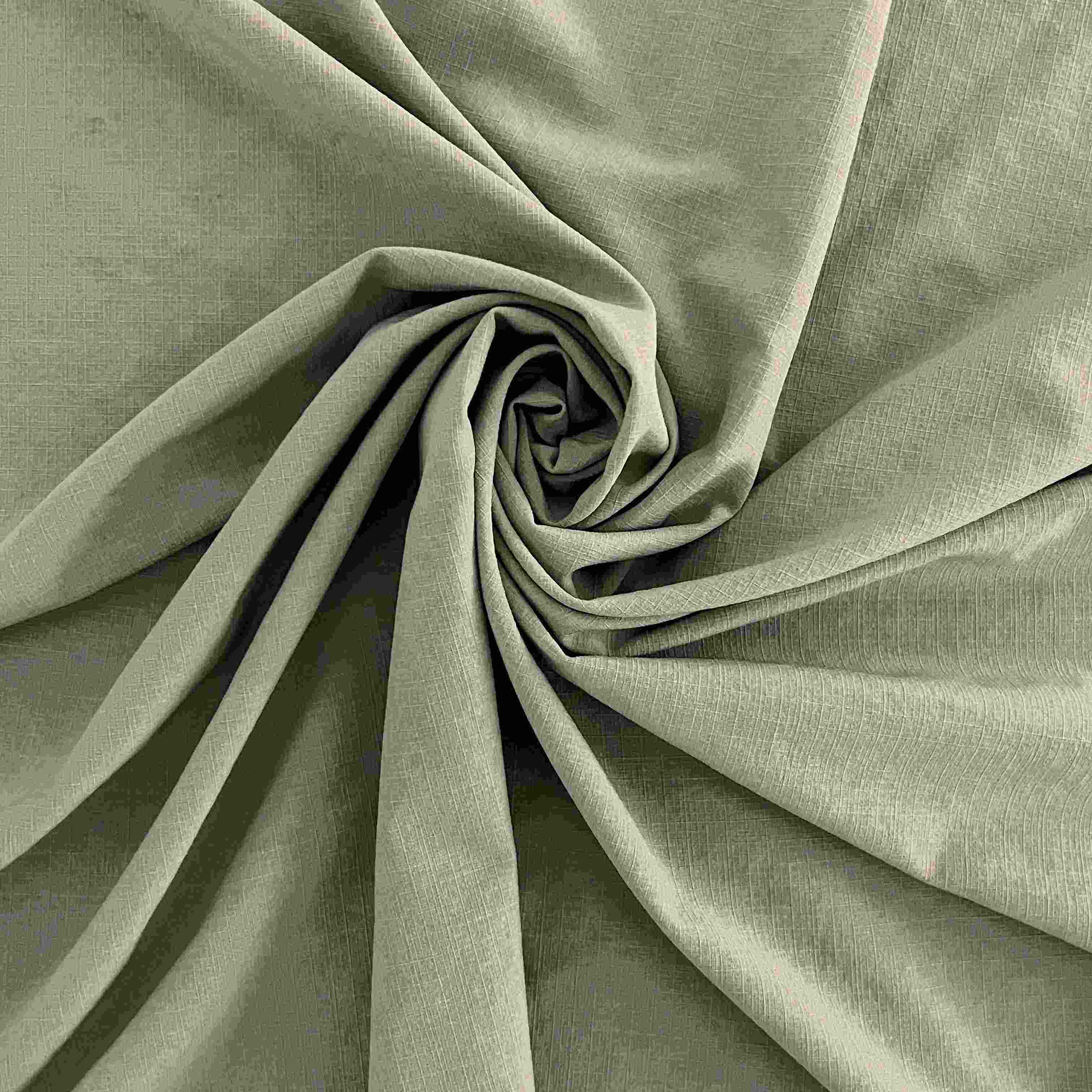

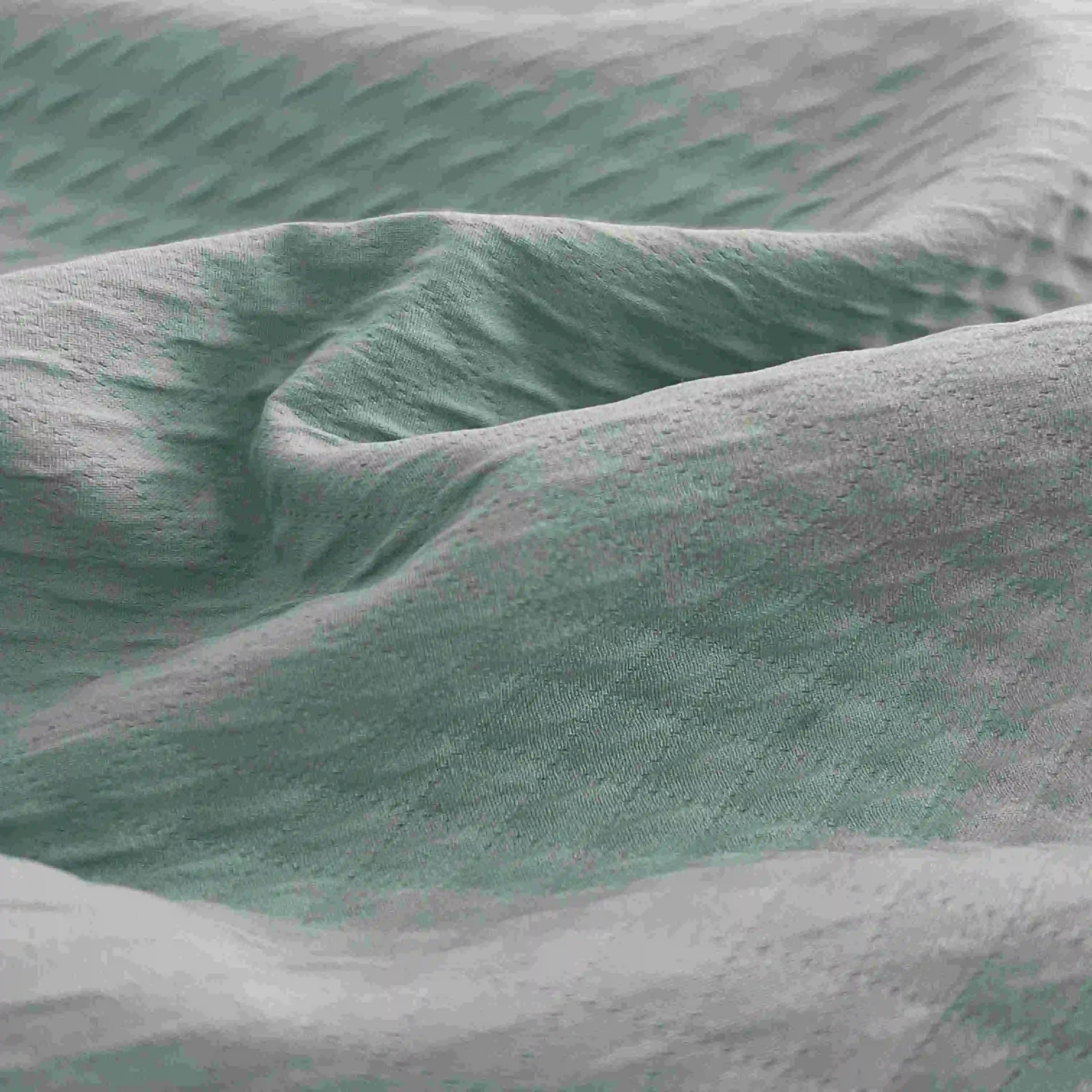

Printed non woven fabric represents a versatile and innovative textile solution that combines the durability of traditional fabrics with modern printing capabilities. This engineered material is created through a bonding process of fibers using mechanical, thermal, or chemical treatments, rather than conventional weaving or knitting methods. The fabric's unique structure allows for excellent printability while maintaining essential characteristics such as breathability, strength, and cost effectiveness. The manufacturing process involves arranging fibers in a web formation, followed by bonding them together to create a cohesive material that can accept various printing techniques, including digital, screen, and heat transfer printing. These fabrics are particularly valued for their ability to maintain color vibrancy and pattern integrity while offering superior ink absorption and quick drying properties. The material's versatility makes it suitable for numerous applications, ranging from decorative items and packaging to fashion accessories and industrial uses. The printing process can accommodate both simple and complex designs, offering excellent color reproduction and pattern consistency across large production runs. Additionally, the fabric's structure allows for enhanced ink penetration, resulting in long lasting prints that resist fading and wear.