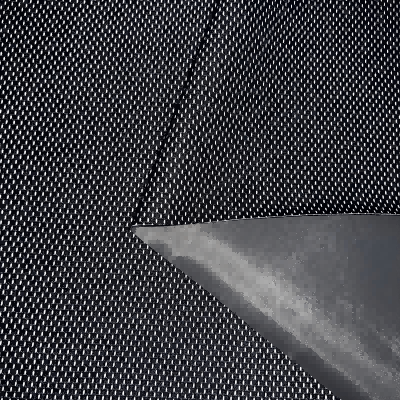

non woven fabric white

Non woven fabric white is a versatile engineered material produced through a specialized manufacturing process that bonds fibers together without traditional weaving or knitting. This innovative textile boasts exceptional versatility across various applications, measuring typically between 10 to 200 GSM depending on specific requirements. The fabric's unique construction method involves mechanically, thermally, or chemically bonding fibers to create a stable structure that maintains its integrity while offering superior filtration and absorption capabilities. The white coloration is achieved through careful selection of raw materials and processing techniques, ensuring consistent appearance and quality. The material exhibits remarkable breathability while maintaining structural stability, making it ideal for medical supplies, filtration systems, and hygiene products. Its distinctive properties include excellent liquid absorption, bacterial barrier effectiveness, and air permeability, all while remaining cost-effective to produce at scale. The manufacturing process allows for customization of thickness, density, and surface textures to meet specific application requirements, from lightweight disposable medical gowns to robust industrial filters. The material's inherent versatility enables it to be treated with additional properties such as hydrophobic or hydrophilic characteristics, further expanding its utility across various sectors.