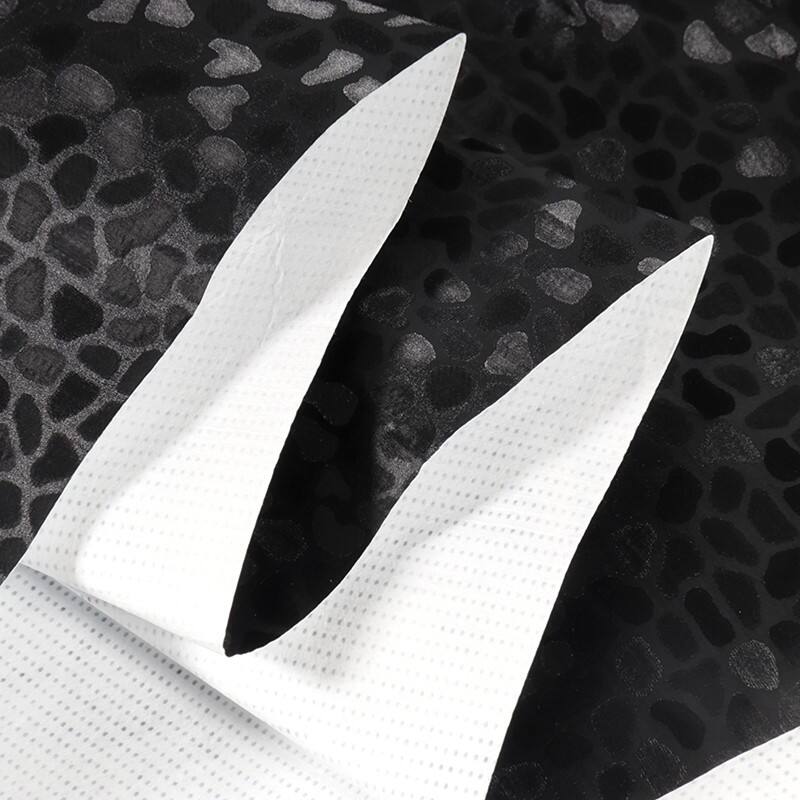

breathable non woven fabric

Breathable non woven fabric represents a revolutionary advancement in textile technology, combining superior air permeability with structural integrity. This innovative material is manufactured through a specialized bonding process of synthetic fibers, creating a fabric that allows free air circulation while maintaining durability. The unique construction method involves arranging fibers in a random pattern and bonding them through mechanical, thermal, or chemical processes, resulting in a material that excels in both breathability and strength. The fabric's microporous structure facilitates effective moisture vapor transmission while providing a barrier against liquid penetration, making it ideal for various applications. Its versatility extends across multiple industries, from medical and hygiene products to agricultural and construction materials. The fabric's inherent properties include excellent air permeability, moisture management, lightweight characteristics, and cost effective production methods. These features make it particularly valuable in applications requiring both comfort and protection, such as surgical masks, protective clothing, and filtration systems. The material's ability to maintain its structural integrity while allowing air flow has made it a preferred choice in both consumer and industrial applications, where breathability and durability are essential requirements.