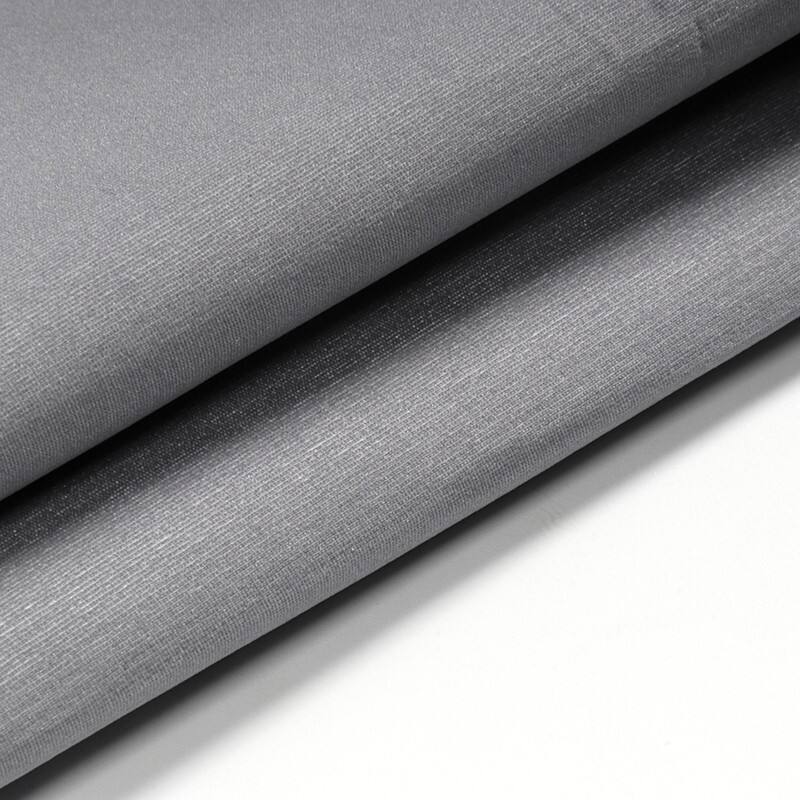

buy non woven fabric

Non woven fabric represents a revolutionary material in the textile industry, manufactured through a process that bonds fibers together without traditional weaving or knitting. When looking to buy non woven fabric, customers encounter a versatile material that offers exceptional durability, cost-effectiveness, and environmental sustainability. These fabrics are created using various techniques including spunbond, meltblown, and needle punch technologies, resulting in materials with specific characteristics suited for different applications. The material's unique manufacturing process allows for customizable properties such as breathability, liquid repellency, and bacterial filtration efficiency. In industrial applications, non woven fabrics serve crucial roles in filtration systems, geotextiles, and automotive components. For medical and hygiene products, they provide essential barriers in surgical masks, protective clothing, and disposable medical supplies. The agricultural sector utilizes these materials for crop protection, soil stabilization, and greenhouse applications. The buying process typically involves considering factors such as material weight, fiber composition, and specific performance requirements, ensuring the selected fabric meets exact application needs.