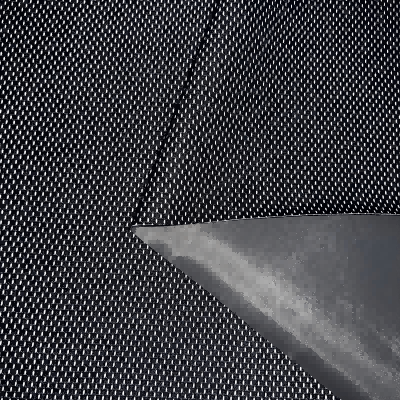

biodegradable non woven fabric

Biodegradable non woven fabric represents a revolutionary advancement in sustainable textile manufacturing, combining eco-consciousness with practical functionality. This innovative material is produced through a specialized bonding process of natural and biodegradable fibers without traditional weaving or knitting methods. The fabric's structure consists of randomly oriented fibers that are mechanically, thermally, or chemically bonded together to create a durable yet environmentally friendly material. What sets this fabric apart is its ability to decompose naturally within a specific timeframe when exposed to proper environmental conditions, leaving no harmful residues behind. The material maintains excellent strength and versatility during its useful life while incorporating various natural fibers such as PLA (Polylactic Acid), plant-based cellulose, and other renewable resources. Its unique manufacturing process allows for customizable properties including thickness, porosity, and surface texture, making it suitable for diverse applications ranging from medical supplies and agricultural products to packaging materials and disposable hygiene products. The fabric also demonstrates remarkable absorption capabilities, breathability, and bacterial resistance, making it an ideal choice for both industrial and consumer applications where environmental impact is a primary concern.