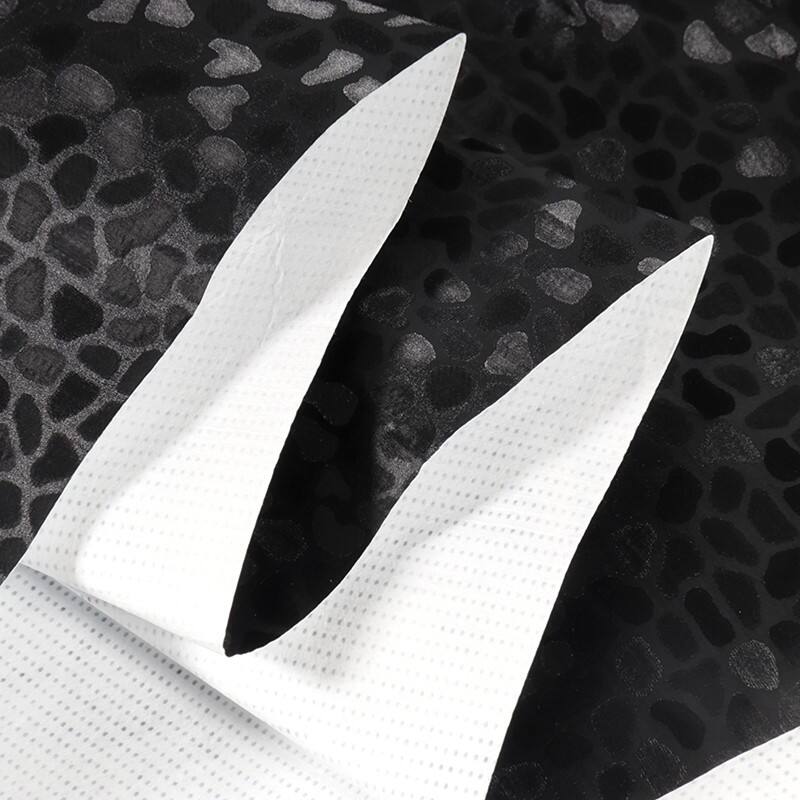

thick non woven fabric

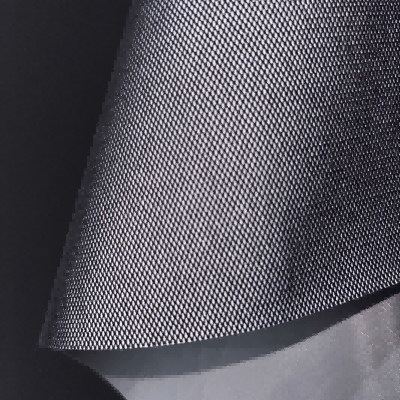

Thick non woven fabric represents a versatile and robust material manufactured through advanced bonding processes without traditional weaving or knitting. This innovative textile solution features densely compressed fibers that create a substantial, durable structure with superior strength and stability. The material's distinctive manufacturing process involves mechanically, thermally, or chemically bonding synthetic or natural fibers, resulting in a fabric that combines exceptional thickness with remarkable durability. The fabric's substantial composition makes it ideal for applications requiring enhanced insulation, filtration, and protective properties. Its unique structure allows for excellent air permeability while maintaining structural integrity, making it particularly valuable in industrial, medical, and consumer applications. The material's thickness can be precisely controlled during manufacturing, typically ranging from 2mm to 10mm, enabling customization for specific end uses. The fabric's non woven construction eliminates the need for complex weaving processes, resulting in cost effective production while maintaining high performance standards. Its versatility extends to various sectors, including automotive interiors, geotextiles, furniture manufacturing, and protective equipment, where its robust nature and reliable performance make it an indispensable material choice.